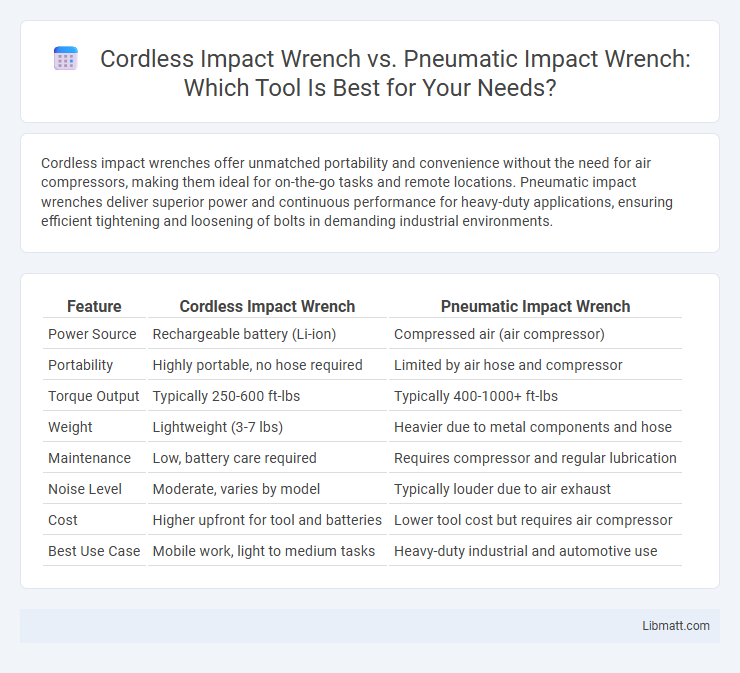

Cordless impact wrenches offer unmatched portability and convenience without the need for air compressors, making them ideal for on-the-go tasks and remote locations. Pneumatic impact wrenches deliver superior power and continuous performance for heavy-duty applications, ensuring efficient tightening and loosening of bolts in demanding industrial environments.

Table of Comparison

| Feature | Cordless Impact Wrench | Pneumatic Impact Wrench |

|---|---|---|

| Power Source | Rechargeable battery (Li-ion) | Compressed air (air compressor) |

| Portability | Highly portable, no hose required | Limited by air hose and compressor |

| Torque Output | Typically 250-600 ft-lbs | Typically 400-1000+ ft-lbs |

| Weight | Lightweight (3-7 lbs) | Heavier due to metal components and hose |

| Maintenance | Low, battery care required | Requires compressor and regular lubrication |

| Noise Level | Moderate, varies by model | Typically louder due to air exhaust |

| Cost | Higher upfront for tool and batteries | Lower tool cost but requires air compressor |

| Best Use Case | Mobile work, light to medium tasks | Heavy-duty industrial and automotive use |

Introduction to Impact Wrenches

Impact wrenches are powerful tools designed to deliver high torque output with minimal effort, essential for fastening and loosening nuts and bolts in automotive and construction tasks. Cordless impact wrenches offer portability and ease of use with rechargeable batteries, while pneumatic impact wrenches rely on compressed air systems, providing consistent power and durability in heavy-duty applications. Understanding the differences helps you choose the right tool for your specific job requirements and work environment.

Key Differences: Cordless vs Pneumatic

Cordless impact wrenches offer unmatched portability and convenience with battery-powered operation, eliminating the need for air compressors and hoses, making them ideal for mobile or remote work settings. Pneumatic impact wrenches, powered by compressed air, typically deliver higher torque and sustained power for heavy-duty applications, but require an air compressor and hose system, limiting mobility. Your choice depends on the balance between the convenience of cordless flexibility and the consistent power output of pneumatic tools for demanding tasks.

Power and Performance Comparison

Cordless impact wrenches offer high torque outputs reaching up to 1,000 Nm, providing strong performance for automotive and construction tasks without the need for an air compressor. Pneumatic impact wrenches typically deliver greater continuous power and faster bolt removal speeds due to unlimited air supply, achieving torque levels often exceeding 1,500 Nm. Battery efficiency and motor technology advancements have narrowed the gap, but pneumatic models remain superior for heavy-duty, high-volume applications.

Portability and Mobility

Cordless impact wrenches offer superior portability and mobility due to their battery-powered design, eliminating the need for air hoses or compressors and allowing use in remote locations or tight spaces. Pneumatic impact wrenches require an air compressor and hose, which restricts movement and makes them less convenient for fieldwork but often deliver consistent power for industrial settings. The cordless models are ideal for tasks requiring flexibility, while pneumatic tools excel in environments with reliable air supply.

Maintenance and Durability

Cordless impact wrenches require less frequent maintenance due to their sealed electric motors and lack of air hoses, making them ideal for clean and portable use. Pneumatic impact wrenches demand regular lubrication and air filter replacement to prevent corrosion and ensure optimal performance over time. While pneumatic models offer superior durability in heavy-duty industrial settings, cordless wrenches provide sufficient longevity with proper battery care and are more resilient to environmental wear.

Noise and Vibration Levels

Cordless impact wrenches generally produce lower noise and vibration levels compared to pneumatic impact wrenches, making them more suitable for prolonged use and indoor environments. Pneumatic impact wrenches generate higher decibel levels, often exceeding 100 dB, which can lead to increased user fatigue and hearing protection requirements. Advanced cordless models incorporate vibration-dampening technology, enhancing comfort and reducing the risk of hand-arm vibration syndrome (HAVS).

Cost Analysis and Long-Term Value

Cordless impact wrenches typically have a higher upfront cost due to battery technology and advanced motor design but offer significant savings on maintenance and operational expenses since they don't require air compressors or hoses. Pneumatic impact wrenches generally have lower initial prices but incur ongoing costs from compressed air system maintenance, energy consumption, and limited portability. For your long-term value, a cordless impact wrench provides flexibility and reduced total cost of ownership, making it a cost-effective investment for diverse applications.

Ideal Applications for Each Type

Cordless impact wrenches excel in mobile and remote applications such as automotive repairs, construction sites, and light-to-medium assembly tasks where portability and convenience are crucial. Pneumatic impact wrenches are ideal for heavy-duty industrial and manufacturing environments, offering sustained power for repetitive tasks like tire changes in professional garages and large-scale machinery assembly. Selecting between the two depends on the required torque, mobility needs, and available power sources.

User Experience and Convenience

Cordless impact wrenches offer superior convenience with their portability and easy operation, eliminating the need for air compressors and cumbersome hoses, which enhances user experience during mobile or remote tasks. Pneumatic impact wrenches provide consistent, powerful torque ideal for heavy-duty industrial use but require a constant air supply, limiting mobility and increasing setup time. Your choice depends on whether you prioritize effortless maneuverability and quick setup or sustained power and durability for intensive applications.

Which Impact Wrench Should You Choose?

Cordless impact wrenches offer greater portability and ease of use with rechargeable batteries, making them ideal for on-the-go tasks and locations without air supply. Pneumatic impact wrenches deliver higher torque and consistent performance, perfect for heavy-duty industrial applications where compressed air systems are readily available. Choose a cordless model for convenience and flexibility, or a pneumatic one for power and durability in demanding environments.

Cordless impact wrench vs pneumatic impact wrench Infographic

libmatt.com

libmatt.com