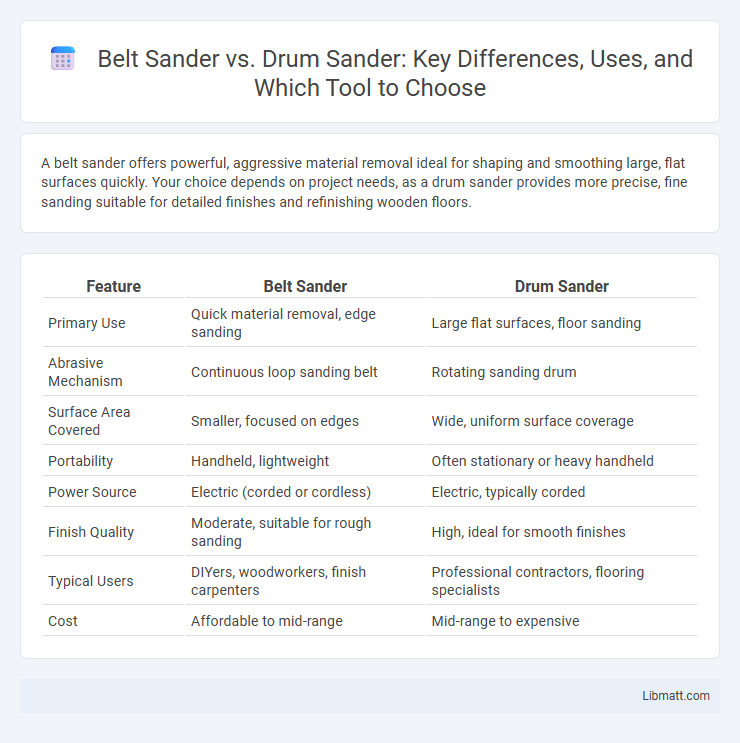

A belt sander offers powerful, aggressive material removal ideal for shaping and smoothing large, flat surfaces quickly. Your choice depends on project needs, as a drum sander provides more precise, fine sanding suitable for detailed finishes and refinishing wooden floors.

Table of Comparison

| Feature | Belt Sander | Drum Sander |

|---|---|---|

| Primary Use | Quick material removal, edge sanding | Large flat surfaces, floor sanding |

| Abrasive Mechanism | Continuous loop sanding belt | Rotating sanding drum |

| Surface Area Covered | Smaller, focused on edges | Wide, uniform surface coverage |

| Portability | Handheld, lightweight | Often stationary or heavy handheld |

| Power Source | Electric (corded or cordless) | Electric, typically corded |

| Finish Quality | Moderate, suitable for rough sanding | High, ideal for smooth finishes |

| Typical Users | DIYers, woodworkers, finish carpenters | Professional contractors, flooring specialists |

| Cost | Affordable to mid-range | Mid-range to expensive |

Introduction to Belt Sanders and Drum Sanders

Belt sanders and drum sanders serve different smoothing and material removal purposes in woodworking and construction. Belt sanders use a continuous loop of sandpaper attached to two drums, ideal for rapid stock removal on rough or uneven surfaces, while drum sanders feature a single, large sanding drum designed for more precise, uniform sanding of boards and panels. Choosing between these tools depends on Your project's needs for speed versus finish quality.

How Belt Sanders Work

Belt sanders operate by moving a continuous loop of sandpaper over two drums at high speed, allowing for rapid material removal on wood, metal, or other surfaces. The powerful motor drives the belt in a linear motion that smooths rough surfaces or removes old finishes efficiently. Adjustable speed settings and variable belt sizes enhance precision and adaptability for various sanding projects.

How Drum Sanders Operate

Drum sanders operate by feeding wood through a rotating cylindrical drum wrapped with abrasive paper, which sands the surface evenly and efficiently. The adjustable drum height allows for precise material removal, making drum sanders ideal for flattening large, rough boards. Their consistent pressure and uniform sanding action produce smooth, flat surfaces with minimal effort compared to manual sanding methods.

Key Differences Between Belt Sanders and Drum Sanders

Belt sanders use a continuous loop of sandpaper moving at high speed to rapidly remove material from wood surfaces, making them ideal for rough sanding and shaping. Drum sanders feature a rotating drum wrapped with sanding material that provides more controlled, precise sanding, especially for smoothing large, flat surfaces with uniform thickness. Your choice between the two depends on whether you need aggressive material removal with a belt sander or fine, even finishing with a drum sander.

Pros and Cons of Belt Sanders

Belt sanders offer powerful, high-speed sanding ideal for rapidly removing material from large wood surfaces, making them perfect for heavy-duty projects. Their portability and efficiency stand out, but they can be less precise and may cause gouging if not handled carefully, especially on delicate finishes. You benefit from faster stock removal, but the lack of fine control requires experience to avoid damaging your workpiece.

Pros and Cons of Drum Sanders

Drum sanders offer powerful stock removal and create smooth, even surfaces on large wood pieces, making them ideal for thicknessing and flattening tasks. The main drawbacks include potential snipe on the edges and a higher price point compared to belt sanders, which may challenge budget-conscious users. Your choice should consider these pros and cons based on the scale of sanding projects and precision requirements.

Best Use Cases for Belt Sanders

Belt sanders excel at heavy material removal, edge sanding, and rapid surface leveling on wood, metal, and other hard materials, making them ideal for rough sanding tasks. Their continuous loop of sandpaper allows for aggressive stock removal on large flat or slightly curved surfaces, perfect for preparing furniture or flooring. Belt sanders are also preferred for shaping and smoothing edges due to their portability and ease of maneuverability.

Best Applications for Drum Sanders

Drum sanders excel in heavy-duty sanding tasks, making them ideal for large wood surfaces such as tabletops, doors, and wide boards where uniform thickness and smooth finish are essential. Their powerful motor and large sanding drum allow precise removal of material, perfect for floor refinishing and leveling uneven wooden substrates. If your project demands consistent surface flatness and efficient stock removal, a drum sander will deliver superior performance compared to a belt sander.

Factors to Consider When Choosing Between the Two

When choosing between a belt sander and a drum sander, consider the scale and precision of your project, as belt sanders are ideal for quick material removal and rough shaping, while drum sanders excel in producing smooth, flat surfaces on large workpieces. Your workspace and portability needs matter, since belt sanders are typically handheld and more maneuverable, whereas drum sanders are often stationary and suited for workshop use. Evaluate the cost, sanding speed, and desired finish to ensure you select the tool that best matches your woodworking or refinishing requirements.

Conclusion: Which Sander is Right for You?

Choosing between a belt sander and a drum sander depends on the scale and precision of your project. Belt sanders excel in rapid material removal on rough surfaces and edges, making them ideal for woodworking and construction tasks requiring aggressive sanding. Drum sanders offer finer control and uniform surface finish, best suited for cabinetry, furniture restoration, and projects demanding smooth, precise results.

Belt sander vs drum sander Infographic

libmatt.com

libmatt.com