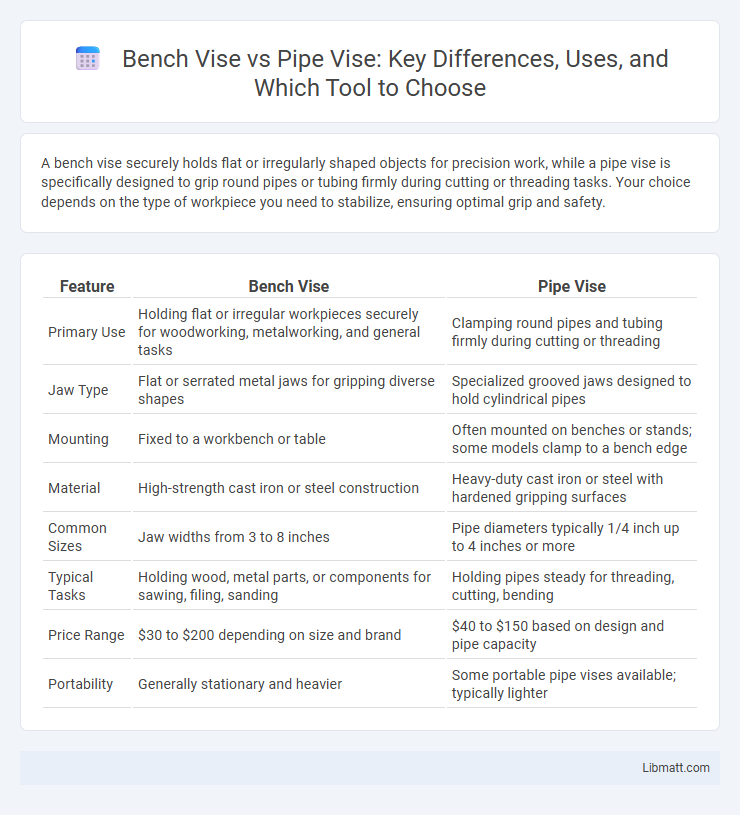

A bench vise securely holds flat or irregularly shaped objects for precision work, while a pipe vise is specifically designed to grip round pipes or tubing firmly during cutting or threading tasks. Your choice depends on the type of workpiece you need to stabilize, ensuring optimal grip and safety.

Table of Comparison

| Feature | Bench Vise | Pipe Vise |

|---|---|---|

| Primary Use | Holding flat or irregular workpieces securely for woodworking, metalworking, and general tasks | Clamping round pipes and tubing firmly during cutting or threading |

| Jaw Type | Flat or serrated metal jaws for gripping diverse shapes | Specialized grooved jaws designed to hold cylindrical pipes |

| Mounting | Fixed to a workbench or table | Often mounted on benches or stands; some models clamp to a bench edge |

| Material | High-strength cast iron or steel construction | Heavy-duty cast iron or steel with hardened gripping surfaces |

| Common Sizes | Jaw widths from 3 to 8 inches | Pipe diameters typically 1/4 inch up to 4 inches or more |

| Typical Tasks | Holding wood, metal parts, or components for sawing, filing, sanding | Holding pipes steady for threading, cutting, bending |

| Price Range | $30 to $200 depending on size and brand | $40 to $150 based on design and pipe capacity |

| Portability | Generally stationary and heavier | Some portable pipe vises available; typically lighter |

Introduction to Bench Vise and Pipe Vise

Bench vises provide a stable clamping solution for woodworking, metalworking, and general repairs by securely holding objects on a workbench. Pipe vises specialize in gripping round pipes or tubing, offering a firm hold for threading, cutting, or assembly tasks. Choosing the right vise depends on your project needs, ensuring maximum efficiency and safety.

Key Differences Between Bench Vise and Pipe Vise

Bench vises provide a flat, solid grip suitable for holding wood, metal, or plastic during cutting or assembly, while pipe vises are specifically designed to securely clamp round pipes and tubing, preventing rotation during threading or welding. Bench vises typically feature smooth jaws or replaceable inserts to protect workpieces, whereas pipe vises incorporate V-shaped or chain mechanisms to accommodate various pipe diameters. The mounting style also differs, with bench vises fixed to a workbench for versatile use, and pipe vises often mounted on stands or attached to workbenches optimized for plumbing and pipefitting tasks.

Design and Structure Comparison

Bench vises feature a flat jaw design with a sturdy base, ideal for holding flat or square objects securely on workbenches. Pipe vises incorporate a V-shaped or semicircular jaw, specifically designed to grip round pipes and tubing, often mounted on stands or walls for better leverage. Your choice depends on whether your projects involve flat materials requiring stable clamping or cylindrical pipes needing precise hold.

Applications and Suitable Tasks

Bench vises are ideal for securely holding flat or irregularly shaped objects during woodworking, metalworking, and assembly tasks, providing stable clamping for drilling, filing, and sawing. Pipe vises specialize in gripping round or cylindrical pipes, tubes, and conduit, making them essential for plumbing, pipe fitting, and threading operations where rotational stability is crucial. Choosing between a bench vise and a pipe vise depends on the shape of the workpiece and the nature of the task, with bench vises excelling in versatile general clamping and pipe vises offering tailored support for pipe-related work.

Material and Build Quality

Bench vises are typically constructed from heavy-duty cast iron or ductile iron, offering robust durability and precise clamping force for woodworking or metalworking tasks. Pipe vises, on the other hand, are often made from forged steel or cast steel to withstand the torque and pressure required for securely holding cylindrical pipes during cutting or threading. The build quality of bench vises emphasizes flat jaw surfaces and smooth operation, while pipe vises prioritize strong gripping mechanisms and durability against wear and deformation.

Installation and Mounting Methods

Bench vices are typically installed on workbenches using bolts through pre-drilled holes in the base, providing a secure and stationary grip for precise tasks. Pipe vises often require mounting on sturdy surfaces or walls using clamps or bolts designed to hold cylindrical objects firmly in place. Your choice depends on whether you need a fixed, flat-surface grip or a method tailored for gripping and turning pipes during plumbing or metalwork projects.

Jaw Types and Grip Efficiency

Bench vises feature flat, textured jaws designed for securely holding a variety of materials including wood, metal, and plastic, providing versatile grip efficiency for general tasks. Pipe vises, on the other hand, have curved, U-shaped or V-shaped jaws specifically engineered to grip cylindrical objects like pipes and tubes with maximum stability and minimal slippage. The specialized jaw design of pipe vises ensures superior grip on round surfaces, while bench vises offer broader functionality for diverse shapes and sizes.

Durability and Maintenance

Bench vises typically feature robust cast iron or steel construction, offering exceptional durability for a wide range of clamping tasks, while pipe vises are specifically designed with reinforced jaws to hold cylindrical objects securely, ensuring long-lasting performance under pressure. Maintenance for bench vises involves regular lubrication of the screw and keeping the jaws clean from debris, whereas pipe vises require periodic inspection of the clamping teeth and hinge points to prevent rust and ensure reliable grip. Choosing the right vise for your needs influences the ease of maintenance and the longevity of the tool in your workshop.

Cost and Value for Money

A bench vise typically offers greater versatility for general workshop tasks, making it a cost-effective choice for those needing a multi-purpose tool. Pipe vises are specialized for holding round pipes securely, often priced lower but limited in function, providing good value if pipe work is your primary focus. Your decision should weigh the upfront cost against the specific applications to maximize value for money based on your project needs.

Choosing the Right Vise for Your Workshop

Selecting the ideal vise depends on the specific tasks and materials you'll be working with in your workshop. Bench vises offer versatility and strong grip for general woodworking, metalworking, and assembly tasks, while pipe vises are specialized for securely holding cylindrical objects like pipes and tubing during cutting or threading. Consider the nature of your projects, material types, and workspace setup to determine whether a bench vise's flat jaw or a pipe vise's clamping mechanism best suits your needs.

Bench vise vs pipe vise Infographic

libmatt.com

libmatt.com