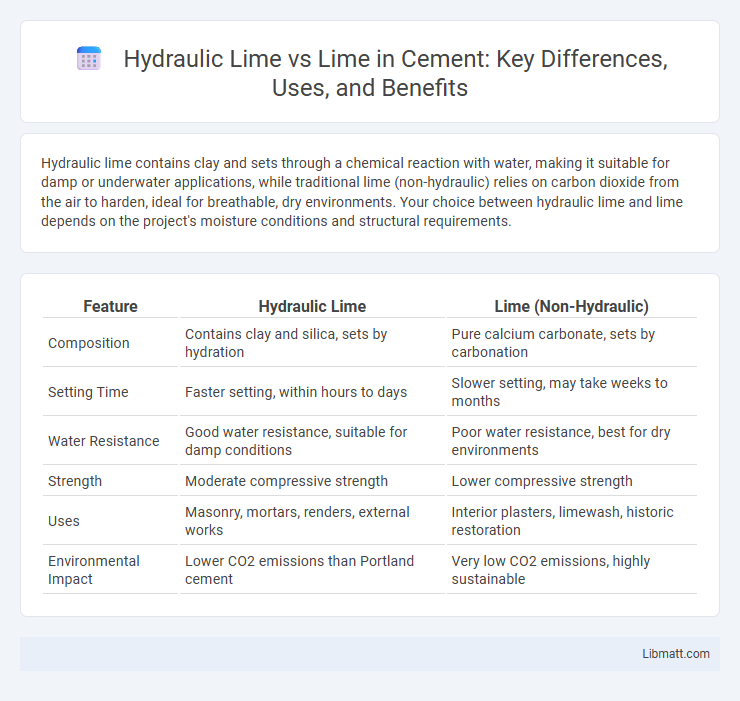

Hydraulic lime contains clay and sets through a chemical reaction with water, making it suitable for damp or underwater applications, while traditional lime (non-hydraulic) relies on carbon dioxide from the air to harden, ideal for breathable, dry environments. Your choice between hydraulic lime and lime depends on the project's moisture conditions and structural requirements.

Table of Comparison

| Feature | Hydraulic Lime | Lime (Non-Hydraulic) |

|---|---|---|

| Composition | Contains clay and silica, sets by hydration | Pure calcium carbonate, sets by carbonation |

| Setting Time | Faster setting, within hours to days | Slower setting, may take weeks to months |

| Water Resistance | Good water resistance, suitable for damp conditions | Poor water resistance, best for dry environments |

| Strength | Moderate compressive strength | Lower compressive strength |

| Uses | Masonry, mortars, renders, external works | Interior plasters, limewash, historic restoration |

| Environmental Impact | Lower CO2 emissions than Portland cement | Very low CO2 emissions, highly sustainable |

Understanding Hydraulic Lime and Lime

Hydraulic lime is a type of lime that sets through a chemical reaction with water, making it suitable for use in damp conditions and underwater applications. Traditional lime, often referred to as non-hydraulic or fat lime, sets primarily through carbonation by reacting with carbon dioxide in the air, requiring exposure to moisture but not water immersion. Understanding the differences between hydraulic lime and traditional lime is crucial for selecting the appropriate lime type based on project requirements, durability needs, and environmental conditions.

Composition Differences: Hydraulic vs Non-Hydraulic Lime

Hydraulic lime contains clay and other silicates, allowing it to set through hydration and carbonation, while non-hydraulic lime is primarily composed of calcium carbonate and sets only by absorbing carbon dioxide from the air. Hydraulic lime's composition enables it to harden underwater or in damp conditions, whereas non-hydraulic lime requires exposure to air and is slower to cure. Understanding these differences helps you select the right lime based on your project's environmental conditions and durability needs.

Setting Mechanisms: Hydraulic vs Air Lime

Hydraulic lime sets through a chemical reaction with water, allowing it to harden underwater and gain strength rapidly due to the formation of calcium silicate hydrates. Air lime, also known as non-hydraulic lime, relies on carbonation, a slow process where it absorbs carbon dioxide from the air to harden and gain strength over time. The setting mechanism of hydraulic lime provides durability in damp conditions, while air lime is better suited for well-ventilated, dry environments.

Key Properties and Performance

Hydraulic lime sets through a chemical reaction with water, offering superior durability and water resistance compared to traditional lime, which sets by carbonation with air. Hydraulic lime contains clay and other impurities that enable it to harden underwater and in damp conditions, making it ideal for masonry exposed to moisture. Your choice between hydraulic lime and traditional lime depends on the required strength, setting time, and environmental exposure of the construction project.

Traditional Uses in Construction

Hydraulic lime is favored in traditional construction for its ability to set underwater and provide strong, durable masonry work in damp environments. Lime, particularly non-hydraulic or lime putty, has been used historically for plastering, whitewashing, and mortar in dry, breathable structures. Your choice between hydraulic lime and lime depends on the specific structural needs, including moisture exposure and desired aesthetic finish.

Advantages of Hydraulic Lime

Hydraulic lime offers superior water resistance and faster setting times compared to traditional lime, making it ideal for external masonry exposed to weather. Its ability to cure underwater and adhere well to various substrates enhances durability in damp environments. This makes hydraulic lime a preferred choice for restoration projects and sustainable construction requiring breathable yet robust materials.

Benefits of Non-Hydraulic (Air) Lime

Non-hydraulic lime, also known as air lime, offers superior breathability and moisture regulation in masonry, preventing trapped moisture and reducing the risk of structural damage. Its flexibility and self-healing properties enhance durability, making it ideal for historic building conservation where preserving original materials is critical. Air lime also provides excellent workability and environmental benefits due to lower energy requirements in production compared to hydraulic lime.

Application Techniques and Suitability

Hydraulic lime sets through a chemical reaction with water, making it ideal for applications requiring faster curing and underwater use, such as foundations and external masonry. Non-hydraulic lime, primarily composed of calcium carbonate, cures by carbonating from the air and is best suited for interior finishes, plastering, and restoration work where breathability and flexibility are essential. Choosing between hydraulic and non-hydraulic lime depends on environmental conditions and structural requirements, with hydraulic lime preferred for damp environments and lime for breathable, decorative surfaces.

Environmental Impact Comparison

Hydraulic lime offers a lower carbon footprint compared to traditional lime due to its reduced calcination temperature and the partial hydraulic setting process that captures more CO2 during curing. Traditional lime, primarily composed of calcium carbonate, releases more CO2 during production and curing, contributing to higher greenhouse gas emissions. The use of hydraulic lime also enhances energy efficiency in construction and promotes sustainability by reducing reliance on Portland cement alternatives with higher environmental impacts.

Choosing the Right Lime for Your Project

Hydraulic lime sets through a chemical reaction with water, making it ideal for external or damp environments, while non-hydraulic lime, often called lime putty or hydrated lime, hardens by carbonation and suits interior or dry applications. Understanding the differences in setting time, breathability, and durability helps you select the right lime for structural integrity and long-term performance. Your project's exposure to moisture and desired finish will determine whether hydraulic or non-hydraulic lime is the optimal choice.

Hydraulic lime vs Lime Infographic

libmatt.com

libmatt.com