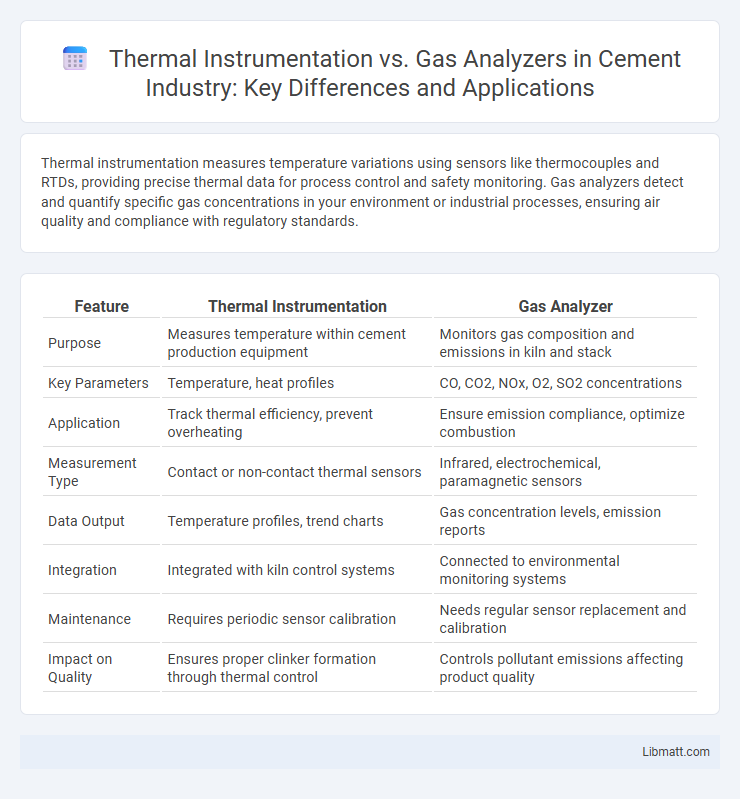

Thermal instrumentation measures temperature variations using sensors like thermocouples and RTDs, providing precise thermal data for process control and safety monitoring. Gas analyzers detect and quantify specific gas concentrations in your environment or industrial processes, ensuring air quality and compliance with regulatory standards.

Table of Comparison

| Feature | Thermal Instrumentation | Gas Analyzer |

|---|---|---|

| Purpose | Measures temperature within cement production equipment | Monitors gas composition and emissions in kiln and stack |

| Key Parameters | Temperature, heat profiles | CO, CO2, NOx, O2, SO2 concentrations |

| Application | Track thermal efficiency, prevent overheating | Ensure emission compliance, optimize combustion |

| Measurement Type | Contact or non-contact thermal sensors | Infrared, electrochemical, paramagnetic sensors |

| Data Output | Temperature profiles, trend charts | Gas concentration levels, emission reports |

| Integration | Integrated with kiln control systems | Connected to environmental monitoring systems |

| Maintenance | Requires periodic sensor calibration | Needs regular sensor replacement and calibration |

| Impact on Quality | Ensures proper clinker formation through thermal control | Controls pollutant emissions affecting product quality |

Introduction to Thermal Instrumentation and Gas Analyzers

Thermal instrumentation measures temperature, heat flow, and thermal properties in industrial processes, using devices like thermocouples, RTDs, and thermal flow meters to ensure accurate thermal monitoring and control. Gas analyzers detect and quantify gas compositions in various environments, employing techniques such as infrared absorption, electrochemical sensors, and mass spectrometry for emissions monitoring and safety compliance. Both instruments play crucial roles in process optimization, environmental monitoring, and ensuring product quality across industries like manufacturing, petrochemical, and environmental protection.

Fundamental Principles of Thermal Instrumentation

Thermal instrumentation operates on the fundamental principle of heat transfer measurement, using temperature changes to monitor and control processes through sensors like thermocouples, resistance temperature detectors (RTDs), and thermistors. These devices detect variations in thermal energy to provide accurate data on temperature, heat flux, or thermal conductivity, essential for maintaining operational efficiency and safety in various industries. Your choice between thermal instrumentation and gas analyzers depends on whether temperature measurement or gas composition analysis is critical to your application.

How Gas Analyzers Work: Core Technologies

Gas analyzers operate using core technologies such as infrared (IR) absorption, electrochemical sensors, and mass spectrometry to detect and quantify gas concentrations with high precision. Unlike thermal instrumentation that measures temperature changes, gas analyzers identify specific gas molecules by analyzing their unique spectral signatures or electrochemical reactions. Understanding how these core technologies function helps you select the right device for applications ranging from environmental monitoring to industrial process control.

Key Applications in Industry and Research

Thermal instrumentation is widely used for temperature monitoring and control in manufacturing processes, power plants, and materials testing, providing precise data critical for maintaining operational safety and efficiency. Gas analyzers primarily serve environmental monitoring, combustion analysis, and industrial emissions testing by detecting and quantifying gas concentrations to ensure regulatory compliance and optimize process performance. Your choice between these instruments depends on whether the primary need is thermal measurement or gas composition analysis in industry and research applications.

Accuracy and Sensitivity: A Comparative Analysis

Thermal instrumentation offers high accuracy in detecting temperature variations, making it ideal for processes requiring precise thermal measurements. Gas analyzers provide superior sensitivity in identifying trace gas concentrations, ensuring accurate analysis of complex gas mixtures. Your choice depends on whether thermal precision or gas detection sensitivity is paramount for your application.

Cost and Maintenance Considerations

Thermal instrumentation typically incurs lower initial costs and demands less frequent maintenance due to its simpler design and fewer moving parts. Gas analyzers, while more expensive upfront, require regular calibration and sensor replacements to maintain accuracy, resulting in higher ongoing maintenance expenses. Evaluating total cost of ownership highlights that thermal instruments offer cost efficiency in low-maintenance environments, whereas gas analyzers justify their cost through precise gas composition analysis in complex applications.

Integration with Modern Industrial Systems

Thermal instrumentation offers seamless integration with modern industrial systems through advanced digital interfaces and IoT connectivity, enabling real-time temperature monitoring and predictive maintenance. Gas analyzers complement this by providing precise gas composition data essential for process optimization and emissions compliance within integrated control systems. Your facility benefits from combining both technologies to achieve comprehensive process monitoring and improved operational efficiency.

Limitations and Challenges of Each Technology

Thermal instrumentation faces limitations such as slower response times and reduced accuracy in environments with fluctuating temperatures or particulate contamination, which can affect heat transfer measurements. Gas analyzers encounter challenges including calibration drift, interference from cross-sensitivity to other gases, and the need for frequent maintenance to ensure sensor reliability in detecting specific gas concentrations. Both technologies must address issues related to environmental conditions and sensor stability to maintain precise and accurate monitoring.

Safety Implications and Regulatory Compliance

Thermal instrumentation provides precise temperature monitoring crucial for preventing overheating and fire hazards, ensuring compliance with safety standards such as NFPA 70E and OSHA regulations. Gas analyzers detect hazardous gas concentrations, vital for maintaining air quality and meeting EPA and OSHA exposure limits to prevent toxic or explosive incidents. Integrating both technologies enhances workplace safety by enabling comprehensive environmental monitoring aligned with regulatory compliance frameworks.

Future Trends: Innovations in Thermal and Gas Sensing

Advancements in thermal instrumentation focus on integrating nanotechnology and MEMS sensors to enhance sensitivity and reduce power consumption, enabling precise temperature measurements in extreme environments. Gas analyzers are evolving with the incorporation of AI-driven data analytics and multi-gas detection capabilities, improving real-time air quality monitoring and industrial safety. Emerging sensor materials like graphene and developments in wireless connectivity are driving the future of both thermal and gas sensing technologies toward more compact, efficient, and intelligent systems.

Thermal instrumentation vs Gas analyzer Infographic

libmatt.com

libmatt.com