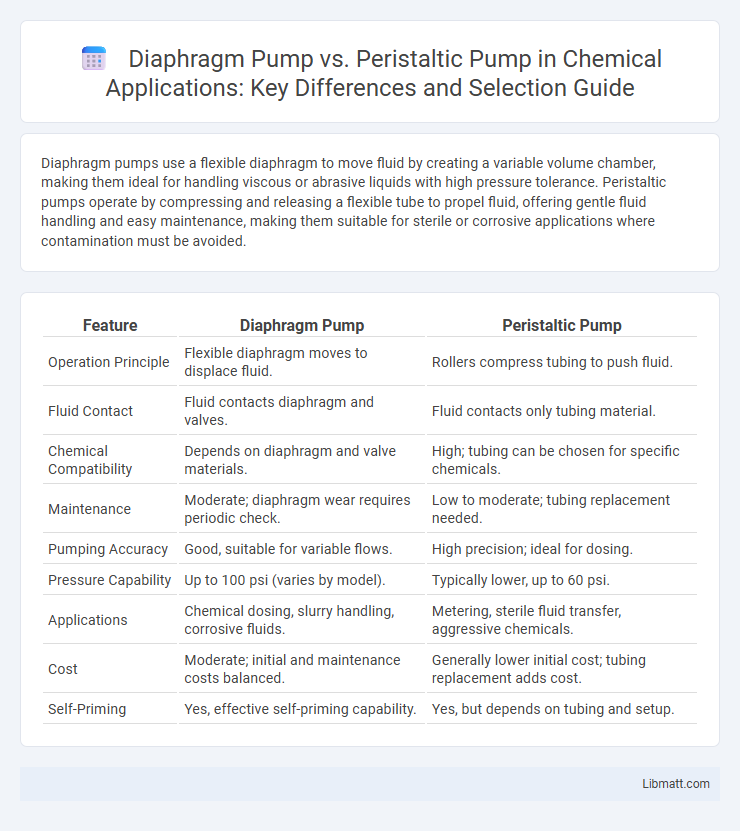

Diaphragm pumps use a flexible diaphragm to move fluid by creating a variable volume chamber, making them ideal for handling viscous or abrasive liquids with high pressure tolerance. Peristaltic pumps operate by compressing and releasing a flexible tube to propel fluid, offering gentle fluid handling and easy maintenance, making them suitable for sterile or corrosive applications where contamination must be avoided.

Table of Comparison

| Feature | Diaphragm Pump | Peristaltic Pump |

|---|---|---|

| Operation Principle | Flexible diaphragm moves to displace fluid. | Rollers compress tubing to push fluid. |

| Fluid Contact | Fluid contacts diaphragm and valves. | Fluid contacts only tubing material. |

| Chemical Compatibility | Depends on diaphragm and valve materials. | High; tubing can be chosen for specific chemicals. |

| Maintenance | Moderate; diaphragm wear requires periodic check. | Low to moderate; tubing replacement needed. |

| Pumping Accuracy | Good, suitable for variable flows. | High precision; ideal for dosing. |

| Pressure Capability | Up to 100 psi (varies by model). | Typically lower, up to 60 psi. |

| Applications | Chemical dosing, slurry handling, corrosive fluids. | Metering, sterile fluid transfer, aggressive chemicals. |

| Cost | Moderate; initial and maintenance costs balanced. | Generally lower initial cost; tubing replacement adds cost. |

| Self-Priming | Yes, effective self-priming capability. | Yes, but depends on tubing and setup. |

Introduction to Diaphragm and Peristaltic Pumps

Diaphragm pumps use a flexible membrane to create suction and discharge fluid, making them ideal for handling abrasive, viscous, or chemically aggressive liquids. Peristaltic pumps operate through a series of rollers compressing a flexible tube, ensuring contamination-free transfer with gentle handling of shear-sensitive fluids. Understanding these mechanisms helps you select the best pump for applications requiring precise fluid control and durability.

Working Principle of Diaphragm Pumps

Diaphragm pumps operate by flexing a diaphragm made from rubber, thermoplastic, or Teflon to create a variable volume chamber that draws fluid in and pushes it out. The reciprocating motion of the diaphragm is typically driven by a mechanical linkage, compressed air, or hydraulic power, ensuring a consistent fluid flow without contamination since the fluid contacts only the pump chamber and diaphragm. This design allows diaphragm pumps to handle abrasive, viscous, and chemically aggressive fluids, making them ideal for industrial, chemical, and pharmaceutical applications.

Working Principle of Peristaltic Pumps

Peristaltic pumps operate by compressing and releasing a flexible tube or hose, creating a peristaltic motion that pushes fluid forward without direct contact with pump components; this design ensures contamination-free pumping and easy maintenance. Your fluid moves through the tubing as rollers or shoes sequentially compress it, mimicking natural peristalsis. This mechanism makes peristaltic pumps ideal for handling aggressive, viscous, or shear-sensitive fluids compared to diaphragm pumps, which rely on a reciprocating diaphragm to move liquid.

Key Design Differences

Diaphragm pumps utilize a flexible diaphragm that moves back and forth to create a variable volume chamber, enabling fluid movement through check valves, while peristaltic pumps employ rollers that compress flexible tubing to push fluids in a controlled manner. Diaphragm pumps excel in handling corrosive and abrasive fluids with high pressures, whereas peristaltic pumps are ideal for sterile, shear-sensitive, or viscous fluids due to their contact-free pumping mechanism. The design of diaphragm pumps involves intricate valve systems and a sealed pumping chamber, contrasting with the simpler tubing and roller assembly of peristaltic pumps, impacting maintenance and fluid compatibility.

Fluid Compatibility and Chemical Resistance

Diaphragm pumps excel in handling abrasive, corrosive, and viscous fluids due to their robust diaphragms made from materials like PTFE or EPDM, ensuring high chemical resistance and broad fluid compatibility. Peristaltic pumps offer superior compatibility with aggressive chemicals and sterile fluids by isolating the fluid within the tubing, often constructed from materials such as silicone, Viton, or Norprene, minimizing contamination risks. Both pump types provide excellent chemical resistance, but the choice depends on the specific fluid properties, including viscosity, particulate content, and the required level of sterility.

Maintenance Requirements and Durability

Diaphragm pumps typically require less frequent maintenance due to their simple design and robust materials, making them suitable for handling abrasive or corrosive fluids with high durability. Peristaltic pumps, while offering precise fluid control and easy sterilization, involve wear on the tubing that necessitates regular replacement to maintain optimal performance and longevity. Choosing between the two depends on application-specific factors such as fluid type, maintenance capabilities, and desired pump lifespan.

Pumping Efficiency and Performance

Diaphragm pumps deliver consistent flow rates and handle high pressures effectively, making them ideal for applications requiring reliable pumping efficiency and robust performance. Peristaltic pumps excel in precise flow control and gentle fluid handling, reducing shear stress and minimizing contamination risks. Your choice between these pumps should consider the specific fluid properties and desired pumping accuracy to maximize operational efficiency.

Typical Applications and Industry Usage

Diaphragm pumps are widely used in industries such as chemical processing, water treatment, and food and beverage for handling abrasive, corrosive, or viscous fluids with precise dosing requirements. Peristaltic pumps excel in medical, pharmaceutical, and laboratory settings where contamination-free, gentle pumping of sterile fluids and aggressive chemicals is essential. Your choice between these pumps depends on the specific application's fluid properties, required flow accuracy, and hygiene standards.

Cost Analysis and Energy Consumption

Diaphragm pumps generally have lower initial costs compared to peristaltic pumps but may incur higher maintenance expenses due to diaphragm wear and replacement frequency. Peristaltic pumps typically consume less energy because they rely on a gentle squeezing mechanism, optimizing efficiency in applications with viscous or abrasive fluids. Evaluating total cost of ownership requires considering pump lifespan, energy consumption rates, and maintenance requirements specific to each pump's operational environment.

Choosing the Right Pump for Your Application

Diaphragm pumps provide reliable air or liquid transfer with strong chemical resistance and the ability to handle viscous fluids and solids, making them ideal for industrial and chemical processes. Peristaltic pumps excel in sterile, precise fluid handling applications, offering gentle pumping with no contamination risk due to their tubing design, which is essential in medical, pharmaceutical, and food industries. Understanding your fluid's properties, such as viscosity, chemical compatibility, and required flow rate, helps you select the right pump to ensure optimal performance and longevity.

Diaphragm pump vs peristaltic pump Infographic

libmatt.com

libmatt.com