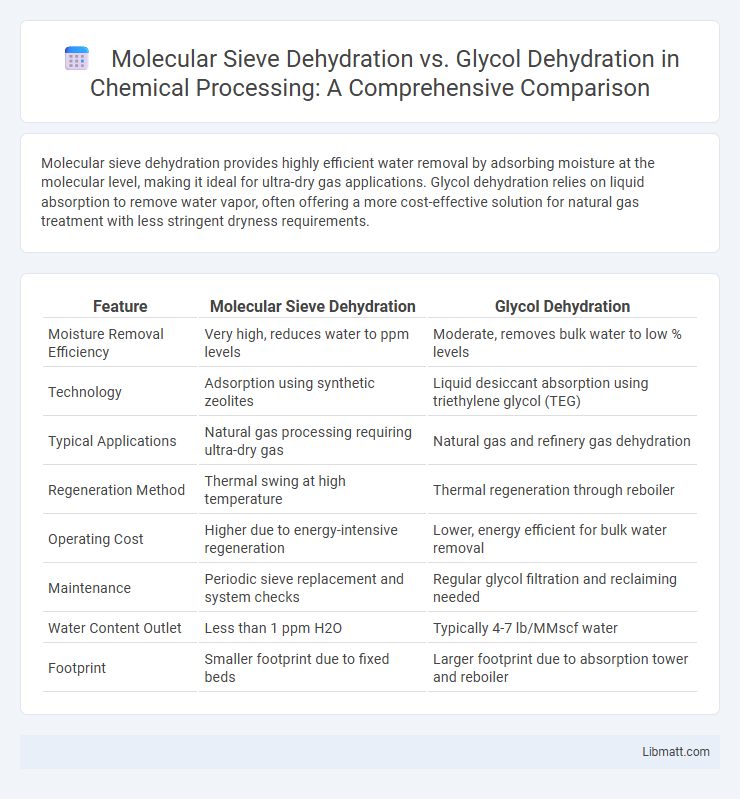

Molecular sieve dehydration provides highly efficient water removal by adsorbing moisture at the molecular level, making it ideal for ultra-dry gas applications. Glycol dehydration relies on liquid absorption to remove water vapor, often offering a more cost-effective solution for natural gas treatment with less stringent dryness requirements.

Table of Comparison

| Feature | Molecular Sieve Dehydration | Glycol Dehydration |

|---|---|---|

| Moisture Removal Efficiency | Very high, reduces water to ppm levels | Moderate, removes bulk water to low % levels |

| Technology | Adsorption using synthetic zeolites | Liquid desiccant absorption using triethylene glycol (TEG) |

| Typical Applications | Natural gas processing requiring ultra-dry gas | Natural gas and refinery gas dehydration |

| Regeneration Method | Thermal swing at high temperature | Thermal regeneration through reboiler |

| Operating Cost | Higher due to energy-intensive regeneration | Lower, energy efficient for bulk water removal |

| Maintenance | Periodic sieve replacement and system checks | Regular glycol filtration and reclaiming needed |

| Water Content Outlet | Less than 1 ppm H2O | Typically 4-7 lb/MMscf water |

| Footprint | Smaller footprint due to fixed beds | Larger footprint due to absorption tower and reboiler |

Introduction to Dehydration Methods in Natural Gas Processing

Molecular sieve dehydration removes water from natural gas through selective adsorption, achieving extremely low water content levels essential for pipeline quality and cryogenic processing. Glycol dehydration, commonly using triethylene glycol (TEG), absorbs water from gas streams, offering cost-effective and continuous water removal for moderate dehydration needs. Your choice between molecular sieve and glycol dehydration depends on achieving target water dew points and operational considerations in natural gas processing.

Overview of Molecular Sieve Dehydration

Molecular sieve dehydration uses synthetic zeolite pellets that selectively adsorb water molecules from gas streams, achieving ultra-low dew points below -100degF, which is critical for natural gas processing and industrial applications requiring high purity. This technology operates efficiently at varying pressures and removes water without chemical consumption, making it a cost-effective and environmentally friendly option compared to glycol dehydration. Your choice of molecular sieve systems ensures reliable protection against hydrate formation and corrosion in pipelines.

Overview of Glycol Dehydration

Glycol dehydration utilizes triethylene glycol (TEG) to absorb water from natural gas through contactor columns, enabling efficient moisture removal before pipeline distribution. This method is widely favored for its cost-effectiveness and ability to handle large gas volumes, maintaining water content below pipeline specifications to prevent hydrate formation. Your gas processing operations benefit from glycol dehydration by reducing corrosion risks and ensuring compliance with industry standards.

Molecular Sieve Dehydration: Working Principle

Molecular sieve dehydration operates by adsorbing water molecules onto microporous crystalline structures, selectively trapping water based on molecular size and polarity differences. This physical adsorption process occurs under specific pressure and temperature conditions, effectively reducing water content in gases and liquids to very low levels. Compared to glycol dehydration, molecular sieves provide higher efficiency in producing ultra-dry hydrocarbon streams, crucial for cryogenic processes and gas dehydration applications.

Glycol Dehydration: Working Principle

Glycol dehydration operates by using triethylene glycol (TEG) to absorb water vapor from natural gas in an absorption tower, where the wet gas contacts the glycol, allowing water molecules to transfer into the liquid phase. The water-rich glycol is then regenerated by heating in a reboiler, removing the absorbed water and enabling the glycol to be reused. This process efficiently reduces water content in natural gas to prevent hydrate formation and corrosion, commonly achieving water dew points below -40degF.

Efficiency Comparison: Molecular Sieve vs. Glycol Dehydration

Molecular sieve dehydration offers superior efficiency compared to glycol dehydration by achieving lower water content levels, often below 1 ppm, making it ideal for ultra-dry gas applications. Glycol dehydration typically removes water to around 50-100 ppm, which may be sufficient for less stringent gas processing but is less effective in preventing hydrate formation or corrosion. Your choice depends on the required dryness level, operational costs, and regeneration complexity, with molecular sieves providing more consistent and reliable dehydration performance.

Operational Considerations and Process Requirements

Molecular sieve dehydration offers superior water removal efficiency, especially for natural gas streams requiring extremely low dew points, operating effectively at high pressure and lower temperatures with minimal chemical regeneration needs. Glycol dehydration involves continuous glycol circulation and regeneration, requiring substantial heat input for reactivation, and is generally better suited for moderate water removal with higher water content and lower operating pressures. Molecular sieves demand frequent regeneration cycles and sensitive handling due to adsorption saturation, while glycol units require vigilant monitoring of corrosion inhibitors, glycol quality, and reclaiming systems to maintain operational stability.

Advantages and Disadvantages of Each Technology

Molecular sieve dehydration offers superior water removal efficiency, achieving dew points as low as -100degF, making it ideal for natural gas processing requiring ultra-dry gas. It operates effectively over a wide temperature range and does not introduce contaminants but involves higher capital costs and requires periodic regeneration with heated gas. Glycol dehydration is cost-effective and simpler to operate, providing dew points around -40degF to -60degF, but is less effective for very low water content and involves risks of glycol contamination and loss, as well as potential corrosion issues.

Cost Analysis: Capital and Operational Expenses

Molecular sieve dehydration typically involves higher capital costs due to advanced adsorption materials and specialized equipment but offers lower operational expenses by minimizing chemical usage and maintenance. Glycol dehydration requires a lower initial investment for simpler absorption units, yet operational expenses can increase over time because of glycol chemical costs, regeneration energy, and contamination management. Your choice should consider long-term cost efficiency, balancing upfront investments with ongoing operational savings specific to your project scale and gas composition.

Choosing the Right Dehydration Method: Key Factors

When selecting between molecular sieve dehydration and glycol dehydration, consider factors like water content in the gas stream, operating pressure, and temperature. Molecular sieves provide efficient water removal for low water content and high purity requirements, while glycol dehydration suits higher water levels and continuous regeneration needs. Your choice hinges on balancing dehydration efficiency, cost, and operational complexity to match process demands.

Molecular sieve dehydration vs glycol dehydration Infographic

libmatt.com

libmatt.com