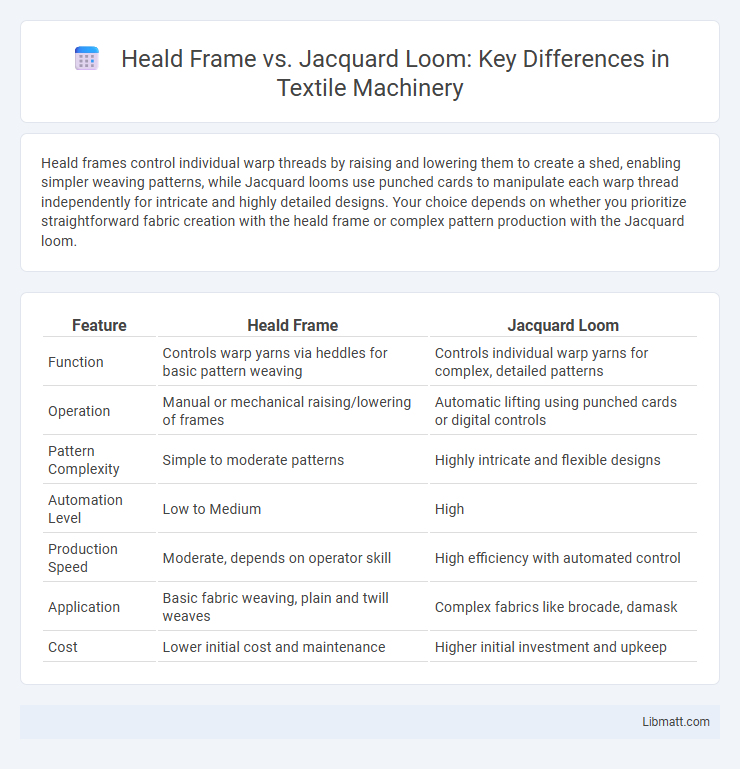

Heald frames control individual warp threads by raising and lowering them to create a shed, enabling simpler weaving patterns, while Jacquard looms use punched cards to manipulate each warp thread independently for intricate and highly detailed designs. Your choice depends on whether you prioritize straightforward fabric creation with the heald frame or complex pattern production with the Jacquard loom.

Table of Comparison

| Feature | Heald Frame | Jacquard Loom |

|---|---|---|

| Function | Controls warp yarns via heddles for basic pattern weaving | Controls individual warp yarns for complex, detailed patterns |

| Operation | Manual or mechanical raising/lowering of frames | Automatic lifting using punched cards or digital controls |

| Pattern Complexity | Simple to moderate patterns | Highly intricate and flexible designs |

| Automation Level | Low to Medium | High |

| Production Speed | Moderate, depends on operator skill | High efficiency with automated control |

| Application | Basic fabric weaving, plain and twill weaves | Complex fabrics like brocade, damask |

| Cost | Lower initial cost and maintenance | Higher initial investment and upkeep |

Introduction to Heald Frame and Jacquard Loom

The Heald frame and Jacquard loom are fundamental components in textile weaving, each serving distinct roles in fabric production. The Heald frame controls warp yarns, allowing them to be raised or lowered to create different weave patterns, whereas the Jacquard loom uses a series of punched cards to control individual warp threads for highly complex designs. Understanding the differences between these mechanisms can enhance your ability to select the right loom for intricate weaving projects.

Historical Background and Development

The Heald frame and Jacquard loom represent significant milestones in textile manufacturing history, with the Heald frame originating in the early handloom period as a mechanism to control warp threads for simpler weave patterns. The Jacquard loom, invented by Joseph Marie Jacquard in 1804, introduced a revolutionary punched card system that automated complex patterns, vastly enhancing weaving efficiency and design possibilities. Your understanding of these innovations highlights the transition from manual to automated weaving processes, shaping modern textile production.

Basic Mechanism and Working Principle

The Heald frame operates by lifting and lowering warp threads through heddles to create a shed for the weft thread to pass, enabling the basic over-under weaving pattern. The Jacquard loom advances this concept by using a series of punched cards to individually control each warp thread's position, allowing for complex patterns and designs. Your choice between the two depends on whether simple weaving efficiency or intricate fabric patterns are the priority.

Types of Textiles Produced

Heald frames are primarily used in plain and twill weave fabrics, which are common in creating durable textiles like cotton and linen. Jacquard looms enable the production of intricate, highly detailed patterns, making them ideal for complex damasks, brocades, and tapestries. Your choice depends on whether you need simpler woven textures or elaborate designs for textile production.

Complexity of Patterns and Designs

The Jacquard loom enables the creation of highly complex and intricate textile patterns by controlling individual warp threads through punched cards, allowing for detailed and varied designs impossible with traditional methods. In contrast, the Heald frame, which uses heddles to lift groups of warp threads, limits pattern complexity to simpler, repetitive designs due to its mechanical constraints. This distinction makes the Jacquard loom a revolutionary tool in textile manufacturing for producing elaborate fabrics such as brocades and damasks.

Production Speed and Efficiency

The Heald frame significantly enhances production speed by allowing faster and more precise shedding of warp threads, resulting in smoother and quicker weaving cycles compared to traditional methods. The Jacquard loom, equipped with a complex punch card system, offers high efficiency in producing intricate patterns but typically operates at a slower pace due to the complexity of its mechanism. Overall, while the Heald frame excels in rapid plain weaving, the Jacquard loom prioritizes detailed design work, impacting its production speed and efficiency accordingly.

Cost and Investment Considerations

Heald frames generally require lower initial investment compared to Jacquard looms due to their simpler mechanical structure and fewer control components, making them more cost-effective for small to medium-scale weaving operations. Jacquard looms, with their complex electronic or punch-card systems for intricate pattern control, involve higher capital costs and maintenance expenses but enable greater design flexibility and production efficiency for large-scale or specialized textile manufacturing. Choosing between the two depends on budget constraints, desired fabric complexity, and long-term production goals, with Jacquard looms offering higher returns on investment in advanced pattern weaving despite the upfront cost.

Applications in Modern Textile Industry

The Heald frame is essential for weaving plain and twill fabrics, offering versatility in producing medium to coarse textiles commonly used in home furnishings and industrial materials. The Jacquard loom excels in creating intricate patterns and complex designs, making it indispensable for high-end fashion, upholstery, and decorative fabrics requiring detailed motifs. Your choice depends on the required fabric complexity and production scale, with the Jacquard loom favored for artistic and personalized textile applications in the modern industry.

Advantages and Disadvantages Comparison

Heald frames offer simpler construction and easier maintenance, making them ideal for small-scale or manual weaving with reduced production costs but limited pattern complexity. Jacquard looms excel in creating highly intricate and detailed patterns by controlling each warp thread independently, boosting design versatility but requiring higher investment and more complex operation. Understanding these trade-offs helps you select the appropriate weaving technology based on production scale, design needs, and budget constraints.

Choosing the Right Loom for Your Needs

Choosing the right loom depends on your weaving complexity and production goals; a Heald frame offers simplicity and is ideal for beginners or small-scale projects, emphasizing manual control and ease of use. The Jacquard loom enables intricate patterns by controlling individual warp threads through punched cards or digital programming, making it essential for detailed textile designs and large-scale production. Evaluating your technical skill, pattern complexity, and budget will guide you to select between the Heald frame for straightforward weaving or the Jacquard loom for advanced, programmable textile creation.

Heald frame vs Jacquard loom Infographic

libmatt.com

libmatt.com