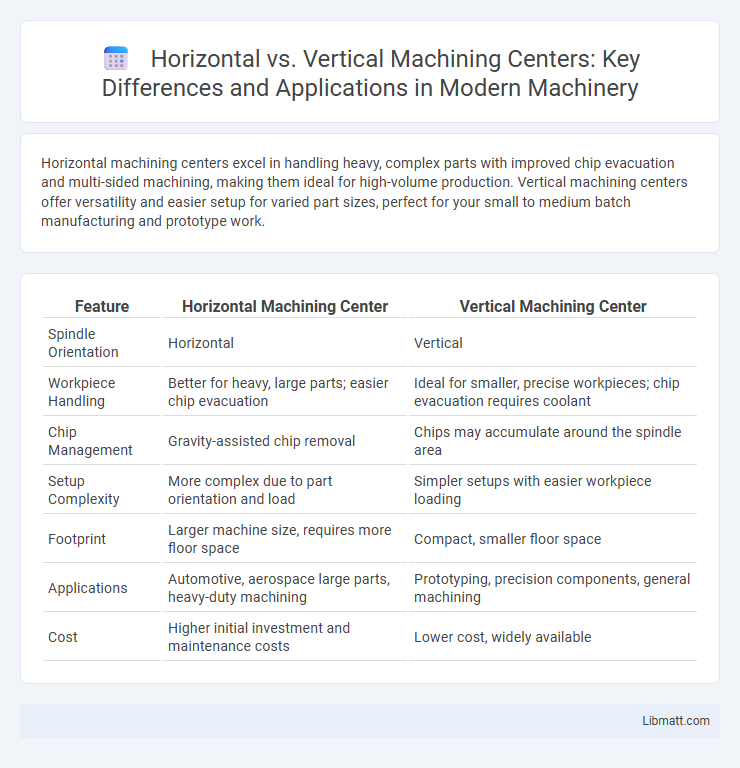

Horizontal machining centers excel in handling heavy, complex parts with improved chip evacuation and multi-sided machining, making them ideal for high-volume production. Vertical machining centers offer versatility and easier setup for varied part sizes, perfect for your small to medium batch manufacturing and prototype work.

Table of Comparison

| Feature | Horizontal Machining Center | Vertical Machining Center |

|---|---|---|

| Spindle Orientation | Horizontal | Vertical |

| Workpiece Handling | Better for heavy, large parts; easier chip evacuation | Ideal for smaller, precise workpieces; chip evacuation requires coolant |

| Chip Management | Gravity-assisted chip removal | Chips may accumulate around the spindle area |

| Setup Complexity | More complex due to part orientation and load | Simpler setups with easier workpiece loading |

| Footprint | Larger machine size, requires more floor space | Compact, smaller floor space |

| Applications | Automotive, aerospace large parts, heavy-duty machining | Prototyping, precision components, general machining |

| Cost | Higher initial investment and maintenance costs | Lower cost, widely available |

Introduction to Machining Centers

Machining centers are advanced CNC machines designed for automated precision manufacturing, categorized mainly into horizontal and vertical configurations. Horizontal machining centers feature a spindle oriented horizontally, ideal for complex, multi-sided workpieces and efficient chip removal, while vertical machining centers have a vertically aligned spindle, offering versatility and ease of access for various machining tasks. Understanding the differences helps you select the optimal center for your production needs, maximizing efficiency and accuracy in machining operations.

Overview of Vertical Machining Centers

Vertical Machining Centers (VMCs) feature a vertically oriented spindle that moves up and down, making them ideal for precision cutting, drilling, and milling of smaller to medium-sized parts. Their design allows easier chip removal and better visibility of the workpiece, enhancing your machining accuracy and efficiency. Commonly used in industries like aerospace and automotive, VMCs provide versatile, high-speed operation for complex component fabrication.

Overview of Horizontal Machining Centers

Horizontal machining centers feature a spindle oriented horizontally, allowing efficient chip evacuation and improved tool access to the workpiece. These centers excel in machining heavy, large, or complex parts, offering enhanced rigidity and stability for precision manufacturing. Common industries using horizontal machining centers include automotive, aerospace, and heavy equipment where multi-sided machining and high productivity are essential.

Key Differences Between Horizontal and Vertical Machining Centers

Horizontal machining centers feature a spindle oriented horizontally, enabling efficient chip evacuation and better access for multi-sided machining, while vertical machining centers have a vertically oriented spindle ideal for detailed surface finishes and easier tool changes. Horizontal centers typically excel in producing complex parts with multiple faces due to their rotary tables and tool magazine capacity, whereas vertical centers are preferred for simpler, high-precision tasks with faster setup times. Your choice depends on the machining complexity, material removal rate, and part geometry requirements.

Advantages of Vertical Machining Centers

Vertical Machining Centers (VMCs) offer superior accessibility to the workpiece, making setups, inspections, and adjustments easier for operators. Their design facilitates efficient chip removal due to gravity, reducing tool wear and enhancing machining precision. Your manufacturing process benefits from cost-effective operation and versatility in handling a wide range of materials and complex geometries.

Advantages of Horizontal Machining Centers

Horizontal Machining Centers (HMCs) offer superior chip evacuation due to their horizontal spindle orientation, enhancing tool life and surface finish. They provide greater rigidity and stability for machining large, heavy parts with multiple faces, reducing setup times and increasing productivity. The ergonomic setup allows for easier automation integration and pallet loading, optimizing workflow in high-volume manufacturing environments.

Typical Applications for Each Machining Center

Horizontal machining centers excel in high-volume production environments such as automotive and aerospace industries, where they efficiently handle complex parts like engine blocks and large structural components. Vertical machining centers are ideal for prototyping and smaller batch production, often used in tool and die making, mold manufacturing, and precision engineering of smaller parts. Your choice depends on the specific application needs, with horizontal centers offering better chip evacuation and vertical centers providing easier tool access and setup.

Cost Considerations and ROI Analysis

Horizontal machining centers generally have higher upfront costs due to their more complex design and larger footprint but offer better chip evacuation and tool life, potentially lowering long-term operational expenses. Vertical machining centers cost less initially and are easier to integrate into smaller shops, making them ideal for lower-volume production or simpler parts, with a quicker ROI for such applications. Evaluating your specific production needs and part complexity will help determine which machine delivers the best balance of cost and return on investment.

Factors to Consider When Choosing Between Horizontal and Vertical

When choosing between a horizontal and vertical machining center, consider factors such as part geometry, production volume, and chip evacuation needs. Horizontal machines excel in handling heavy, complex parts with better chip removal, while vertical machines are ideal for smaller, simpler components and offer easier tool changes. Assess your machining accuracy requirements and workspace layout to determine which center aligns best with your manufacturing goals.

Conclusion: Selecting the Right Machining Center for Your Needs

Choosing between a horizontal and vertical machining center depends on your production volume, part geometry, and material type. Horizontal centers excel in high-volume, heavy-duty machining with better chip evacuation, while vertical centers are ideal for complex, multi-axis parts requiring precision. Assessing your specific manufacturing requirements ensures your investment maximizes efficiency and part quality.

Horizontal vs vertical machining center Infographic

libmatt.com

libmatt.com