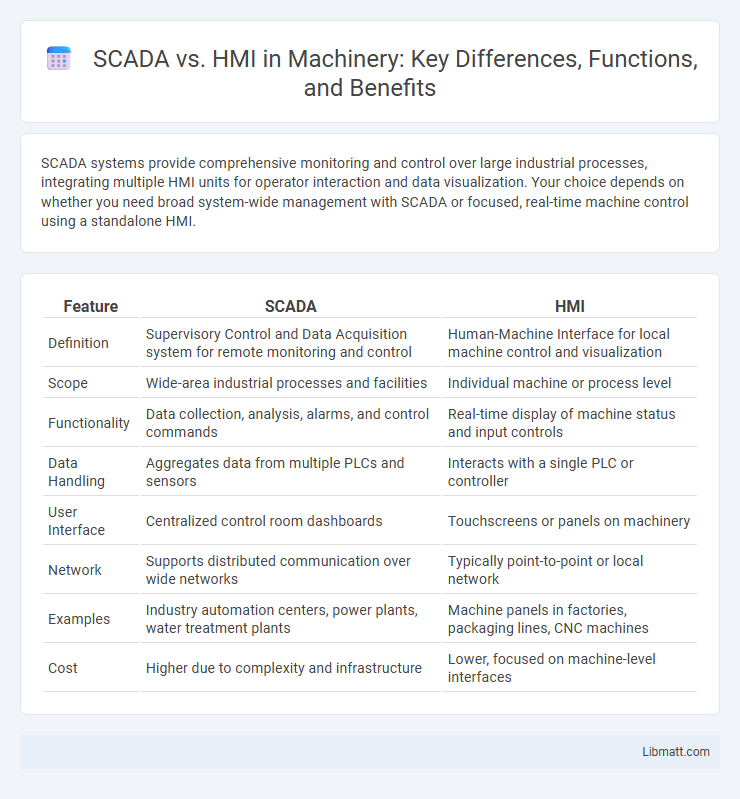

SCADA systems provide comprehensive monitoring and control over large industrial processes, integrating multiple HMI units for operator interaction and data visualization. Your choice depends on whether you need broad system-wide management with SCADA or focused, real-time machine control using a standalone HMI.

Table of Comparison

| Feature | SCADA | HMI |

|---|---|---|

| Definition | Supervisory Control and Data Acquisition system for remote monitoring and control | Human-Machine Interface for local machine control and visualization |

| Scope | Wide-area industrial processes and facilities | Individual machine or process level |

| Functionality | Data collection, analysis, alarms, and control commands | Real-time display of machine status and input controls |

| Data Handling | Aggregates data from multiple PLCs and sensors | Interacts with a single PLC or controller |

| User Interface | Centralized control room dashboards | Touchscreens or panels on machinery |

| Network | Supports distributed communication over wide networks | Typically point-to-point or local network |

| Examples | Industry automation centers, power plants, water treatment plants | Machine panels in factories, packaging lines, CNC machines |

| Cost | Higher due to complexity and infrastructure | Lower, focused on machine-level interfaces |

Introduction to SCADA and HMI

SCADA (Supervisory Control and Data Acquisition) systems are designed for real-time monitoring and control of industrial processes across multiple locations, integrating sensors, controllers, and communication networks to gather data and automate operations. HMI (Human-Machine Interface) serves as the graphical user interface within SCADA systems, enabling operators to interact with machinery, visualize process data, and execute commands efficiently. Both SCADA and HMI play critical roles in industrial automation, with SCADA providing overarching system management and HMI facilitating user interaction.

Core Functions of SCADA Systems

SCADA systems primarily function to monitor and control industrial processes remotely by collecting real-time data from sensors and equipment across multiple locations. They enable centralized supervision, alarm management, and data logging to ensure efficient and safe operations. Your ability to analyze this comprehensive data supports proactive decision-making and minimizes downtime in complex infrastructures.

Essential Features of HMI Interfaces

HMI interfaces provide real-time data visualization through intuitive graphical displays, enabling operators to monitor industrial processes efficiently. Essential features include customizable dashboards, touch-screen controls, alarms, and event logging for rapid response and system troubleshooting. These interfaces facilitate seamless interaction between humans and machines by simplifying complex data into user-friendly formats.

Primary Differences Between SCADA and HMI

SCADA (Supervisory Control and Data Acquisition) systems provide broad, centralized control and data acquisition across large industrial processes, often spanning multiple locations. HMI (Human-Machine Interface) serves as the localized interface for operators to interact with a specific machine or process, focusing on real-time monitoring and control. The primary difference lies in SCADA's system-wide oversight and data aggregation capabilities versus HMI's role as a user interface dedicated to individual equipment or process control.

Architecture Comparison: SCADA vs HMI

SCADA (Supervisory Control and Data Acquisition) systems feature a distributed architecture that integrates multiple components such as remote terminal units (RTUs), programmable logic controllers (PLCs), communication networks, and central monitoring stations to enable centralized control and data acquisition across large-scale industrial processes. In contrast, HMI (Human-Machine Interface) architecture is typically a localized system focused on providing operators with real-time graphical visualization and control through a user interface directly connected to PLCs or controllers. SCADA's multi-tiered architecture supports extensive data collection and analytics, while HMI emphasizes streamlined, operator-level interaction for machine-specific monitoring and control.

Use Case Scenarios for SCADA and HMI

SCADA systems are designed for large-scale industrial processes requiring real-time data acquisition, remote monitoring, and control across multiple sites, such as power plants, water treatment facilities, and oil refineries. HMI interfaces are optimized for local operator interaction with machinery or production lines, providing detailed visualization and control at the machine level in manufacturing and automation environments. Your choice between SCADA and HMI depends on whether you need comprehensive system-wide supervision or focused operator control at specific equipment points.

Integration and Interoperability Considerations

SCADA systems offer comprehensive integration capabilities across multiple devices and networks, enabling centralized control and monitoring of large-scale industrial processes. HMI interfaces prioritize user-friendly interaction with specific machines or systems, often requiring compatibility with SCADA or PLC protocols for seamless communication. Ensuring interoperability involves selecting open standards like OPC UA and industrial Ethernet, which facilitate smooth data exchange and integration between SCADA and HMI components.

Security Implications in SCADA and HMI

SCADA systems manage critical infrastructure and require robust security measures to prevent cyberattacks that can disrupt entire operations, while HMIs primarily serve as user interfaces with more limited exposure to external threats. Security implications in SCADA include vulnerabilities to unauthorized access, malware, and data breaches that could compromise large-scale industrial control processes, whereas HMI security focuses more on protecting user authentication and preventing unauthorized command execution. To safeguard your industrial environment, implementing strong encryption, network segmentation, and continuous monitoring is essential for both SCADA and HMI systems.

Trends and Advances in SCADA and HMI Technologies

Recent advances in SCADA and HMI technologies emphasize enhanced cybersecurity, real-time data analytics, and cloud integration for improved system monitoring and control. Trends include the adoption of IIoT (Industrial Internet of Things) to enable remote access, predictive maintenance, and AI-driven decision-making processes. Your industrial operations benefit from these innovations by achieving greater efficiency, reliability, and scalability in managing complex automation systems.

Choosing the Right Solution: Key Factors to Consider

Choosing the right solution between SCADA and HMI systems depends on the complexity and scale of the industrial process being managed. SCADA systems are ideal for large-scale operations requiring real-time data acquisition, remote monitoring, and centralized control across multiple sites, while HMI is better suited for local machine or process control with simpler interface needs. Evaluating factors such as system integration capabilities, data analytics requirements, scalability, and budget constraints is crucial to determine the optimal solution for effective industrial automation and control.

SCADA vs HMI Infographic

libmatt.com

libmatt.com