Cambering involves shaping a surface or structure to have a slight, intentional curve to improve strength or drainage, while straightening refers to making a surface or object flat or aligned without curvature. Your choice between cambering and straightening depends on whether enhanced structural integrity or a flat, even finish is required for the specific application.

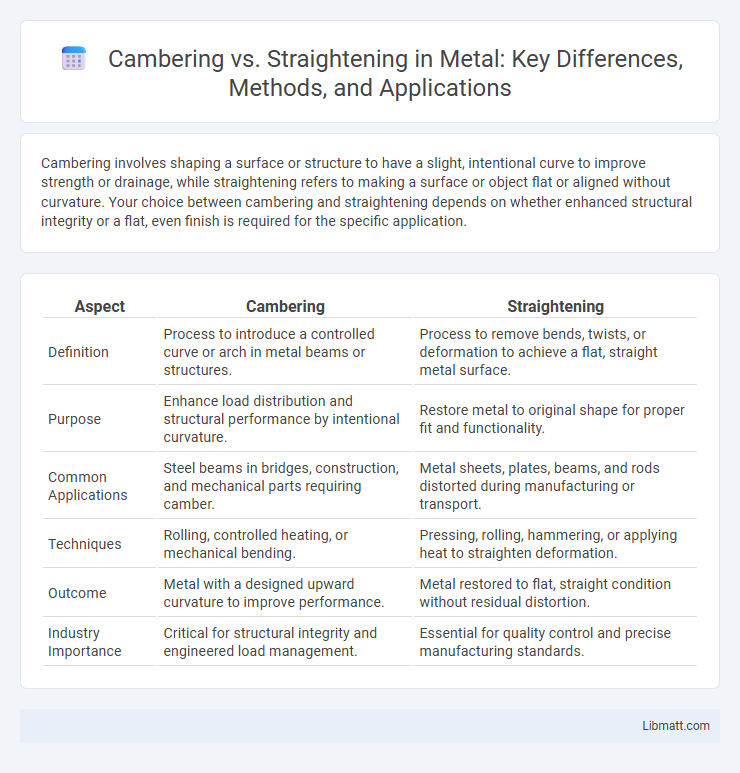

Table of Comparison

| Aspect | Cambering | Straightening |

|---|---|---|

| Definition | Process to introduce a controlled curve or arch in metal beams or structures. | Process to remove bends, twists, or deformation to achieve a flat, straight metal surface. |

| Purpose | Enhance load distribution and structural performance by intentional curvature. | Restore metal to original shape for proper fit and functionality. |

| Common Applications | Steel beams in bridges, construction, and mechanical parts requiring camber. | Metal sheets, plates, beams, and rods distorted during manufacturing or transport. |

| Techniques | Rolling, controlled heating, or mechanical bending. | Pressing, rolling, hammering, or applying heat to straighten deformation. |

| Outcome | Metal with a designed upward curvature to improve performance. | Metal restored to flat, straight condition without residual distortion. |

| Industry Importance | Critical for structural integrity and engineered load management. | Essential for quality control and precise manufacturing standards. |

Introduction to Cambering and Straightening

Cambering and straightening are essential processes in metal fabrication that shape and correct materials to meet structural and design requirements. Cambering introduces a slight curve or arch to beams, enhancing load-bearing capacity and resistance to bending under stress. Straightening removes unwanted bends or distortions, restoring the material's original alignment to ensure precision and structural integrity for your projects.

Definition of Cambering

Cambering is the intentional upward curve built into structural elements such as beams or bridges to counteract deflection caused by loads, improving load distribution and overall strength. Straightening refers to the process of removing distortions or bends from materials to restore their original shape and alignment. Understanding cambering helps you enhance structural performance by preemptively addressing potential sagging issues.

Definition of Straightening

Straightening is the process of correcting the alignment of materials or structures by removing bends, warps, or curves to achieve a flat or true surface. It ensures components meet precise dimensional tolerances and maintain structural integrity, especially in metalworking and construction. You benefit from improved performance and longevity when choosing straightening over cambering, which intentionally adds a curve for specific load-bearing purposes.

Key Differences Between Cambering and Straightening

Cambering involves creating a slight arch or curve in a structural element to counteract deflections under load, while straightening focuses on restoring a deformed member back to its original linear shape. The key difference lies in purpose: cambering adds intentional curvature for enhanced load distribution, whereas straightening removes undesired bends or distortions. Your choice depends on whether you need to improve structural performance through curvature or correct existing misalignments.

Applications of Cambering in Industry

Cambering is widely applied in construction and manufacturing to improve load distribution and structural integrity in bridges, beams, and metal sheets. This technique enhances durability and reduces material stress by introducing a controlled curvature that counteracts deflection under load. In the automotive and aerospace industries, cambering optimizes aerodynamic performance and component alignment, contributing to increased safety and efficiency.

Applications of Straightening in Industry

Straightening is widely applied in industries such as automotive manufacturing, shipbuilding, and steel production to correct deformations in metal sheets and structural components. This process enhances dimensional accuracy and ensures integrity in parts like chassis frames, metal beams, and pipelines. High-precision straightening techniques improve assembly efficiency and reduce material waste in industrial fabrication.

Benefits of Cambering

Cambering improves structural performance by increasing load-bearing capacity and reducing deflection in beams and girders. This method enhances durability and safety in construction by counteracting the natural sagging caused by weight and environmental factors. Optimized cambering results in longer spans and reduced material usage, contributing to cost-effective and efficient engineering designs.

Advantages of Straightening

Straightening enhances structural integrity by aligning materials precisely, reducing the risk of weak points and improving load distribution. Your projects benefit from increased durability and a smoother finish, which leads to easier assembly and better performance. It also minimizes material waste and repair costs compared to cambering, making it a cost-effective solution in construction and manufacturing.

Selecting the Right Process: Cambering vs Straightening

Selecting the right process between cambering and straightening depends on the desired shape correction and structural application; cambering imparts a controlled, intentional curvature to beams for load-bearing efficiency, while straightening removes unwanted bends or distortions to restore the original alignment. Cambering is ideal for enhancing structural performance in bridges and long-span beams by adding precise upward curves, whereas straightening is essential in situations requiring exact flatness and uniformity for safety and design compliance. Understanding material properties, project specifications, and load requirements ensures optimal process selection to achieve structural integrity and performance goals.

Conclusion: Choosing the Best Method for Your Project

Cambering enhances structural integrity by creating a deliberate upward curve, ideal for long-span beams subject to heavy loads. Straightening corrects deformations in beams, restoring original alignment without affecting load-bearing characteristics. Your choice depends on whether your project prioritizes improved load distribution or precise geometric correction.

cambering vs straightening Infographic

libmatt.com

libmatt.com