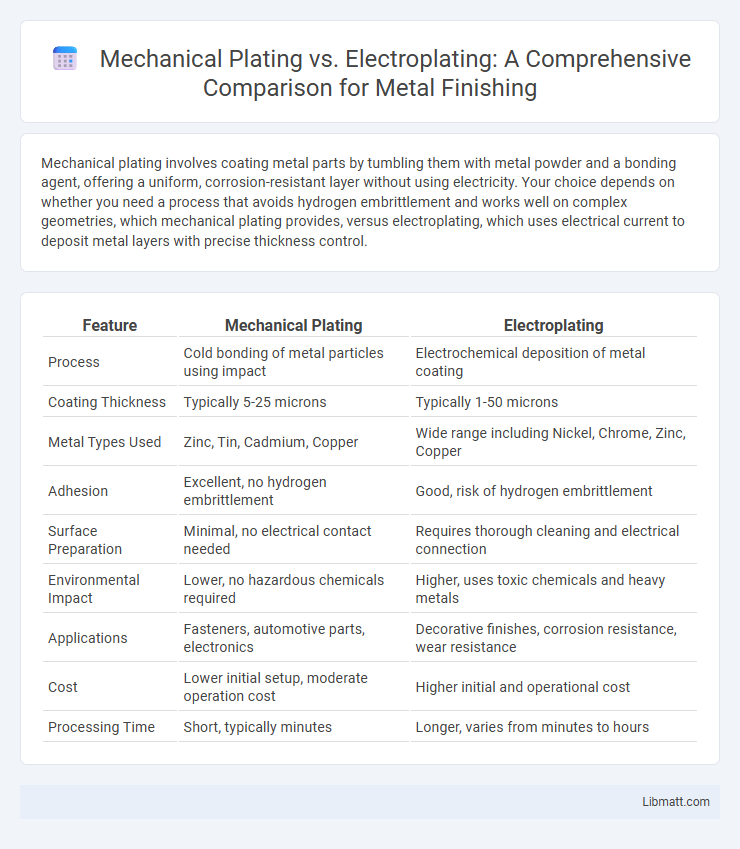

Mechanical plating involves coating metal parts by tumbling them with metal powder and a bonding agent, offering a uniform, corrosion-resistant layer without using electricity. Your choice depends on whether you need a process that avoids hydrogen embrittlement and works well on complex geometries, which mechanical plating provides, versus electroplating, which uses electrical current to deposit metal layers with precise thickness control.

Table of Comparison

| Feature | Mechanical Plating | Electroplating |

|---|---|---|

| Process | Cold bonding of metal particles using impact | Electrochemical deposition of metal coating |

| Coating Thickness | Typically 5-25 microns | Typically 1-50 microns |

| Metal Types Used | Zinc, Tin, Cadmium, Copper | Wide range including Nickel, Chrome, Zinc, Copper |

| Adhesion | Excellent, no hydrogen embrittlement | Good, risk of hydrogen embrittlement |

| Surface Preparation | Minimal, no electrical contact needed | Requires thorough cleaning and electrical connection |

| Environmental Impact | Lower, no hazardous chemicals required | Higher, uses toxic chemicals and heavy metals |

| Applications | Fasteners, automotive parts, electronics | Decorative finishes, corrosion resistance, wear resistance |

| Cost | Lower initial setup, moderate operation cost | Higher initial and operational cost |

| Processing Time | Short, typically minutes | Longer, varies from minutes to hours |

Introduction to Mechanical Plating and Electroplating

Mechanical plating is a cold welding process where metal particles are mechanically bonded to a substrate through impact and friction, creating a uniform, corrosion-resistant coating ideal for complex parts. Electroplating involves using an electric current to reduce dissolved metal cations, depositing a thin, precise metallic layer on a conductive surface to enhance appearance and resistance. Both methods offer distinct advantages in surface protection and finish quality, tailored to specific industrial applications.

How Mechanical Plating Works

Mechanical plating involves tumbling parts with metal powder, water, and special chemicals to create a uniform coating through impact and cold welding. This process produces corrosion-resistant and conductive layers without the use of electricity, making it ideal for delicate components sensitive to heat or electrical stress. Your parts gain enhanced durability and performance through a controlled, environmentally friendly method distinct from electroplating.

How Electroplating Works

Electroplating works by passing an electric current through a solution containing metal ions, causing these ions to deposit onto the surface of the workpiece, creating a thin, uniform metallic coating. This process enhances corrosion resistance, improves appearance, and increases surface hardness by forming a strong metallurgical bond between the substrate and the plated layer. Understanding electroplating helps you choose the right surface treatment for your parts based on durability and finish requirements.

Key Differences Between Mechanical Plating and Electroplating

Mechanical plating involves cold welding metal powder onto a substrate through mechanical impact, creating a uniform coating without heat, while electroplating uses electrical current to deposit metal ions from a solution onto the surface. Mechanical plating is ideal for complex geometries and heat-sensitive materials, offering superior corrosion resistance, whereas electroplating provides excellent adhesion and thickness control but may cause thermal distortion. Your choice between these methods depends on the material properties, desired coating characteristics, and application environment.

Material Compatibility: Mechanical vs Electroplating

Mechanical plating accommodates a broader range of materials, including soft metals like aluminum and brass, without causing heat stress or distortion, which is common in electroplating due to electrical current exposure. Electroplating excels with conductive substrates such as steel and copper, enabling uniform metal deposition but often struggles with non-conductive or heat-sensitive materials. Material compatibility in mechanical plating hinges on the physical impact of metal powders, whereas electroplating depends on electrical conductivity and chemical bath interactions for effective coating adherence.

Coating Thickness and Uniformity

Mechanical plating typically achieves a coating thickness of 0.0002 to 0.001 inches, offering excellent uniformity even on complex geometries due to its tumbling process. Electroplating allows more precise control over coating thickness, often ranging from 0.0001 to 0.002 inches, but may result in less uniform layers on intricate parts because of uneven current distribution. Mechanical plating is favored for consistent thickness and uniform coverage without hydrogen embrittlement risk, while electroplating excels in precision thickness control for simpler shapes.

Corrosion Resistance Comparison

Mechanical plating offers superior corrosion resistance by creating a uniform, dense coating of metal particles, often zinc or nickel, firmly bonded to the substrate without altering its heat treatment. Electroplating provides a thicker but less uniform layer, which can be prone to cracking and corrosion if not properly controlled through precise current and bath chemistry management. The mechanical plating process reduces hydrogen embrittlement risk, enhancing longevity in corrosive environments compared to electroplated parts.

Environmental Impact and Safety Considerations

Mechanical plating significantly reduces hazardous waste generation compared to electroplating, as it uses non-toxic materials and avoids toxic chemicals like cyanide and heavy metals commonly found in electroplating solutions. Your choice of mechanical plating supports safer working environments by minimizing exposure to harmful fumes and reducing the need for extensive wastewater treatment. Electroplating, while effective for corrosion resistance and finish, often requires stringent environmental controls due to toxic sludge and chemical discharge risks.

Cost Analysis: Mechanical Plating vs Electroplating

Mechanical plating generally offers lower operational costs compared to electroplating due to reduced energy consumption and minimal use of hazardous chemicals. Electroplating involves higher expenses related to electricity, chemical solutions, and stricter environmental compliance, increasing the overall cost. Your choice between these methods should consider the specific project requirements and budget constraints to optimize cost-efficiency.

Best Applications for Each Plating Method

Mechanical plating excels in applications requiring uniform coating on complex geometries and delicate components, such as fasteners, aerospace parts, and electronics, due to its low heat process that prevents warping. Electroplating is best suited for decorative finishes and corrosion resistance on metals like automotive parts, jewelry, and household appliances, offering precise layer control and a wide range of material options. Understanding your specific needs will help determine the ideal plating method to enhance durability and appearance.

Mechanical Plating vs Electroplating Infographic

libmatt.com

libmatt.com