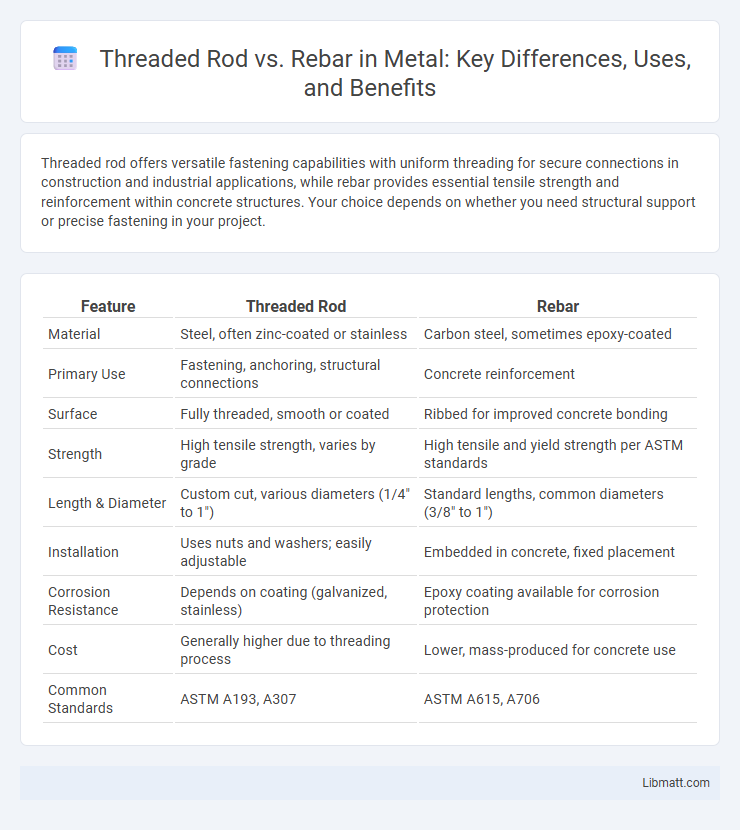

Threaded rod offers versatile fastening capabilities with uniform threading for secure connections in construction and industrial applications, while rebar provides essential tensile strength and reinforcement within concrete structures. Your choice depends on whether you need structural support or precise fastening in your project.

Table of Comparison

| Feature | Threaded Rod | Rebar |

|---|---|---|

| Material | Steel, often zinc-coated or stainless | Carbon steel, sometimes epoxy-coated |

| Primary Use | Fastening, anchoring, structural connections | Concrete reinforcement |

| Surface | Fully threaded, smooth or coated | Ribbed for improved concrete bonding |

| Strength | High tensile strength, varies by grade | High tensile and yield strength per ASTM standards |

| Length & Diameter | Custom cut, various diameters (1/4" to 1") | Standard lengths, common diameters (3/8" to 1") |

| Installation | Uses nuts and washers; easily adjustable | Embedded in concrete, fixed placement |

| Corrosion Resistance | Depends on coating (galvanized, stainless) | Epoxy coating available for corrosion protection |

| Cost | Generally higher due to threading process | Lower, mass-produced for concrete use |

| Common Standards | ASTM A193, A307 | ASTM A615, A706 |

Overview: Threaded Rod vs Rebar

Threaded rods provide versatile fastening solutions with uniform threads along their entire length, making them ideal for adjustable connections and anchoring in construction and machinery. Rebar, or reinforcing bar, is specifically designed to enhance concrete's tensile strength, featuring ribbed surfaces for better bonding within concrete structures. Your choice depends on whether the application requires structural reinforcement (rebar) or flexible fastening and tensioning capabilities (threaded rod).

Material Composition and Properties

Threaded rods are typically made from steel alloys such as carbon steel or stainless steel, featuring uniform threading along their length that provides high tensile strength and corrosion resistance depending on the material grade. Rebar, primarily composed of carbon steel with a deformed surface pattern, is designed to bond firmly with concrete, enhancing structural reinforcement and load distribution in construction projects. Your choice between threaded rods and rebar should consider the specific material properties, including strength, ductility, and resistance to environmental factors, to ensure optimal performance in your application.

Manufacturing Processes

Threaded rods are manufactured by cutting and threading steel rods through processes such as rolling or machining, which create precise helical grooves to facilitate fastening applications. Rebar is produced by hot rolling steel billets into long bars with distinctive surface ribs that enhance concrete adhesion and structural integrity. The contrasting manufacturing techniques result in threaded rods being suited for mechanical fastening, while rebar provides tensile reinforcement in concrete construction.

Common Applications and Uses

Threaded rods are extensively used in construction for anchoring, fastening, and connecting components in concrete, wood, and steel structures, offering precise tension adjustments. Rebar primarily reinforces concrete in foundations, slabs, beams, and columns, enhancing tensile strength and structural integrity in buildings and infrastructure. Both materials serve critical roles in construction, with threaded rods suited for versatile fastening needs and rebar essential for concrete reinforcement.

Strength and Load-Bearing Capacities

Threaded rods offer high tensile strength and are ideal for applications requiring precise length adjustments and secure fastening under tension. Rebar provides superior compressive strength, making it essential for reinforcing concrete structures in load-bearing construction. Your choice depends on whether you prioritize tensile load handling with threaded rods or compressive reinforcement with rebar.

Installation Methods and Techniques

Threaded rod installation involves cutting rods to desired lengths, then securing them with nuts and washers for adjustable fastening in concrete or steel structures. Rebar installation requires tying steel bars together using wire ties and placing them within concrete forms to reinforce structural integrity. Threaded rods allow more precise tension adjustments, while rebar emphasizes fixed positioning to enhance load-bearing capacity during concrete curing.

Cost Considerations

Threaded rods generally offer a more cost-effective solution compared to rebar due to their ease of installation and reduced labor expenses. Rebar costs can fluctuate with market demand for steel, often making it more expensive for large-scale projects. Your choice should weigh these cost factors against the specific structural requirements of your construction project.

Corrosion Resistance and Durability

Threaded rods made from stainless steel or coated alloys offer superior corrosion resistance compared to traditional steel rebar, making them ideal for environments exposed to moisture or chemicals. This enhanced durability extends the lifespan of structures by minimizing rust-related weakening and structural failure. Choosing threaded rods can improve the longevity and reliability of your construction projects under harsh conditions.

Building Codes and Standards Compliance

Threaded rods and rebar each comply with specific building codes and standards relevant to their construction applications, with rebar adhering to ASTM A615 or A706 standards for reinforced concrete structures while threaded rods typically meet ASTM A193 or A307 standards for tension and anchoring purposes. Your choice depends on project requirements, as rebar is mandated in reinforced concrete for strength and durability, whereas threaded rods are used for fastening and load transfer in structural assemblies. Ensuring your materials meet local building codes such as the International Building Code (IBC) or ACI standards is critical for safety and regulatory compliance.

Choosing the Right Option: Key Factors

Choosing between threaded rod and rebar depends on your project's load requirements, environmental exposure, and installation needs. Threaded rods offer superior adjustability and ease of connection for mechanical fastening, while rebar provides enhanced tensile strength and reinforcement in concrete structures. Assessing factors like corrosion resistance, structural design, and cost-efficiency ensures you select the most suitable option for durability and performance.

Threaded Rod vs Rebar Infographic

libmatt.com

libmatt.com