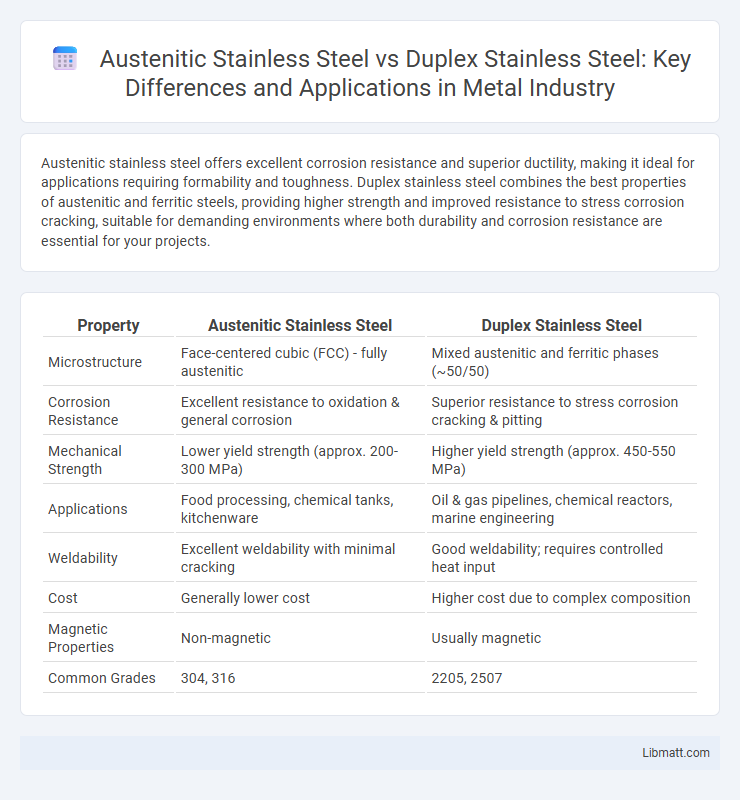

Austenitic stainless steel offers excellent corrosion resistance and superior ductility, making it ideal for applications requiring formability and toughness. Duplex stainless steel combines the best properties of austenitic and ferritic steels, providing higher strength and improved resistance to stress corrosion cracking, suitable for demanding environments where both durability and corrosion resistance are essential for your projects.

Table of Comparison

| Property | Austenitic Stainless Steel | Duplex Stainless Steel |

|---|---|---|

| Microstructure | Face-centered cubic (FCC) - fully austenitic | Mixed austenitic and ferritic phases (~50/50) |

| Corrosion Resistance | Excellent resistance to oxidation & general corrosion | Superior resistance to stress corrosion cracking & pitting |

| Mechanical Strength | Lower yield strength (approx. 200-300 MPa) | Higher yield strength (approx. 450-550 MPa) |

| Applications | Food processing, chemical tanks, kitchenware | Oil & gas pipelines, chemical reactors, marine engineering |

| Weldability | Excellent weldability with minimal cracking | Good weldability; requires controlled heat input |

| Cost | Generally lower cost | Higher cost due to complex composition |

| Magnetic Properties | Non-magnetic | Usually magnetic |

| Common Grades | 304, 316 | 2205, 2507 |

Introduction to Austenitic and Duplex Stainless Steels

Austenitic stainless steels are characterized by their high chromium and nickel content, providing excellent corrosion resistance and excellent formability, making them ideal for food processing and chemical industries. Duplex stainless steels combine austenitic and ferritic microstructures, offering superior strength and enhanced resistance to stress corrosion cracking, often used in marine and petrochemical environments. Understanding the distinct properties of these stainless steel types can help you select the best material for your application's durability and performance requirements.

Chemical Composition Differences

Austenitic stainless steels primarily contain high levels of chromium (16-26%) and nickel (6-22%), with low carbon content, giving them excellent corrosion resistance and ductility. Duplex stainless steels combine approximately equal proportions of austenite and ferrite phases, with chromium content ranging from 19-28% and lower nickel content (4-8%), enhanced with molybdenum (2-5%) for superior strength and chloride stress corrosion resistance. The increased chromium and molybdenum content in duplex stainless steels significantly improve pitting and crevice corrosion resistance compared to austenitic grades.

Microstructure Comparison

Austenitic stainless steels feature a single-phase face-centered cubic (FCC) microstructure that offers excellent corrosion resistance and high ductility, making them ideal for applications requiring formability. Duplex stainless steels combine a balanced microstructure of approximately 50% austenite (FCC) and 50% ferrite (body-centered cubic, BCC), resulting in superior strength and improved resistance to stress corrosion cracking. Your choice between these materials depends on the specific performance characteristics needed for corrosion resistance and mechanical strength.

Mechanical Properties and Strength

Austenitic stainless steels exhibit excellent ductility and toughness with tensile strengths typically ranging from 515 to 750 MPa, making them ideal for high-corrosion environments requiring formability. Duplex stainless steels combine austenitic and ferritic microstructures, offering superior mechanical strength with yield strengths around 450 to 650 MPa and tensile strengths up to 850 MPa, nearly twice that of austenitic types. The duplex grade's enhanced strength and improved stress corrosion cracking resistance make it preferable for applications demanding higher load-bearing capacity and durability.

Corrosion Resistance Analysis

Austenitic stainless steels, primarily composed of high chromium and nickel content, exhibit excellent corrosion resistance in acidic and oxidizing environments, making them ideal for chemical processing and marine applications. Duplex stainless steels combine the benefits of austenitic and ferritic structures, offering superior resistance to stress corrosion cracking and chloride-induced pitting, especially in aggressive chloride environments. Your choice between these alloys should consider the specific corrosive agents present and mechanical stress factors to ensure optimal performance and longevity.

Weldability and Fabrication

Austenitic stainless steels exhibit excellent weldability due to their high ductility and resistance to cracking during fabrication, making them ideal for complex welding processes. Duplex stainless steels combine the benefits of austenitic and ferritic grades, offering superior strength and enhanced corrosion resistance, but require controlled heat input during welding to avoid phase imbalance and ensure optimal mechanical properties. Fabrication of duplex stainless steels demands precise thermal management and skilled welding techniques to prevent issues such as sensitization and intermetallic phase formation that can compromise weld integrity.

Applications and Industry Use

Austenitic stainless steel is widely used in the food processing, chemical, and medical industries due to its excellent corrosion resistance and formability, making it ideal for kitchen equipment, surgical instruments, and chemical containers. Duplex stainless steel, combining austenitic and ferritic properties, excels in offshore oil and gas, marine, and chemical processing applications by offering higher strength and superior resistance to stress corrosion cracking. Choosing between these materials depends on your operational environment's corrosion challenges and mechanical strength requirements.

Cost and Economic Considerations

Austenitic stainless steel typically incurs higher initial costs due to greater nickel content but offers excellent corrosion resistance and formability, making it suitable for a wide range of applications. Duplex stainless steel provides a cost-effective alternative with lower nickel content and enhanced strength, allowing for thinner sections and reduced material usage, which can lead to significant long-term savings. Economic considerations favor duplex stainless steel in projects requiring high strength and corrosion resistance, especially in chloride-rich environments, where lifecycle costs and maintenance are minimized.

Lifespan and Maintenance Requirements

Austenitic stainless steel offers excellent corrosion resistance and requires minimal maintenance, making it ideal for environments with moderate stress and exposure. Duplex stainless steel combines austenitic and ferritic properties, providing superior strength and enhanced resistance to stress corrosion cracking, which results in a longer lifespan in harsh conditions. Maintenance for duplex stainless is generally less frequent compared to austenitic grades, especially in aggressive environments like chemical processing and marine applications.

Choosing Between Austenitic and Duplex Stainless Steels

Austenitic stainless steels offer excellent corrosion resistance and formability, making them ideal for applications requiring high ductility and weldability, especially in mildly corrosive environments. Duplex stainless steels combine austenitic and ferritic properties, providing superior strength and enhanced resistance to stress corrosion cracking and pitting, suitable for harsh industrial conditions like chemical processing and marine environments. Selecting between the two depends on balancing mechanical strength requirements, corrosion resistance needs, and cost considerations specific to the application.

Austenitic Stainless vs Duplex Stainless Infographic

libmatt.com

libmatt.com