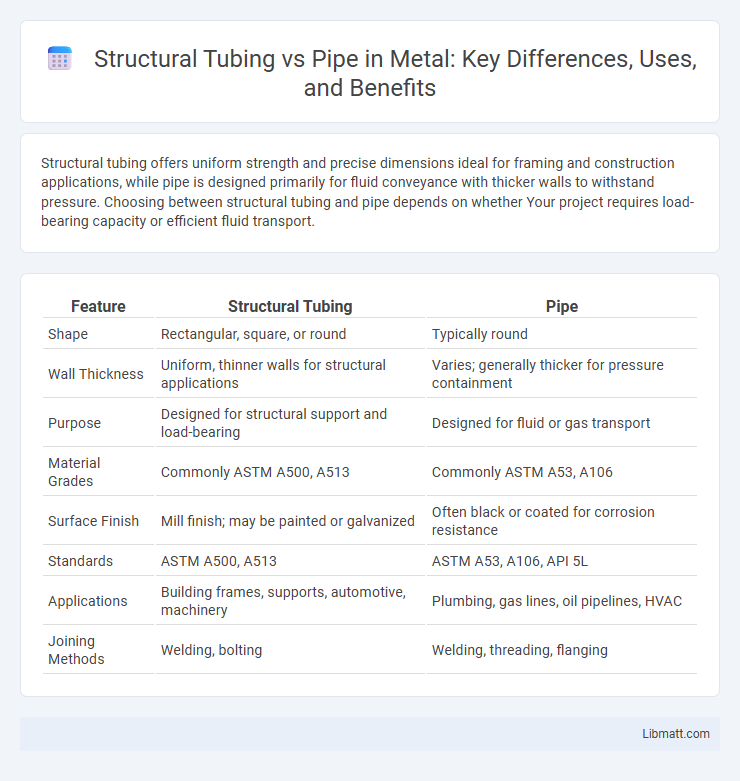

Structural tubing offers uniform strength and precise dimensions ideal for framing and construction applications, while pipe is designed primarily for fluid conveyance with thicker walls to withstand pressure. Choosing between structural tubing and pipe depends on whether Your project requires load-bearing capacity or efficient fluid transport.

Table of Comparison

| Feature | Structural Tubing | Pipe |

|---|---|---|

| Shape | Rectangular, square, or round | Typically round |

| Wall Thickness | Uniform, thinner walls for structural applications | Varies; generally thicker for pressure containment |

| Purpose | Designed for structural support and load-bearing | Designed for fluid or gas transport |

| Material Grades | Commonly ASTM A500, A513 | Commonly ASTM A53, A106 |

| Surface Finish | Mill finish; may be painted or galvanized | Often black or coated for corrosion resistance |

| Standards | ASTM A500, A513 | ASTM A53, A106, API 5L |

| Applications | Building frames, supports, automotive, machinery | Plumbing, gas lines, oil pipelines, HVAC |

| Joining Methods | Welding, bolting | Welding, threading, flanging |

Introduction to Structural Tubing and Pipe

Structural tubing is a type of hollow steel section commonly used in construction and manufacturing for its strength, uniform shape, and versatility. Pipe is specifically designed to transport fluids and gases, featuring thicker walls and precise dimensions to handle pressure and flow requirements. Understanding the differences between structural tubing and pipe helps you select the appropriate material for your project's load-bearing or fluid transport needs.

Defining Structural Tubing: Key Characteristics

Structural tubing is a type of hollow steel section designed for load-bearing applications with uniform cross-sectional dimensions. Unlike pipe, which is primarily intended for fluid transport and measured by nominal diameter and schedule, structural tubing is categorized by precise outside dimensions and wall thickness for strength and stability in construction. Its key characteristics include high strength-to-weight ratio, consistent shape, and resistance to torsion and bending, making it ideal for frameworks and support structures.

Pipe Explained: Purpose and Common Uses

Pipe is designed primarily for transporting fluids and gases, with its cylindrical shape and standardized dimensions ensuring efficient flow and pressure handling. Common uses of pipe include plumbing systems, gas distribution, and industrial processes that require fluid conveyance. Structural tubing, in contrast, is mainly used for load-bearing applications in construction and frameworks due to its geometric versatility and strength.

Differences in Manufacturing Processes

Structural tubing is typically manufactured through cold forming processes like roll forming or extrusion, which produces uniform shapes such as rectangular, square, or circular profiles with precise dimensions. In contrast, pipes are commonly created using welding or seamless extrusion techniques designed to withstand internal pressure, resulting in thicker walls and less emphasis on geometric perfection. Understanding these manufacturing differences helps you select the right material for either structural support or fluid transport applications.

Dimensional Standards: Tubing vs. Pipe

Structural tubing is manufactured to precise dimensional standards with consistent outside dimensions and wall thicknesses, designed primarily for strength and uniformity in construction applications. Pipe dimensions are based on nominal pipe size (NPS) and schedule, emphasizing internal diameter and pressure ratings for fluid transport rather than precise external dimensions. Your choice between tubing and pipe depends on whether you prioritize dimensional accuracy for structural integrity or internal capacity for fluid flow.

Strength and Load-Bearing Capabilities

Structural tubing offers superior strength and load-bearing capabilities due to its uniform cross-sectional area and consistent wall thickness, which distribute stress evenly. Pipe, primarily designed for fluid transport, has varying wall thicknesses and is less optimized for structural loads, making it less ideal for heavy load applications. Engineering projects requiring high strength and stability frequently prefer structural tubing for its enhanced performance under tension and compression.

Applications in Construction and Engineering

Structural tubing offers superior strength and stability ideal for frameworks, supports, and load-bearing components in construction and engineering projects. Pipe is primarily used for fluid transport systems, such as plumbing, HVAC, and industrial piping, where pressure resistance and flow capacity are critical. Your choice depends on whether the application demands structural integrity or fluid conveyance.

Cost Considerations and Availability

Structural tubing generally offers lower costs compared to pipe due to its standardized shapes and widespread production for construction applications. Pipe tends to be more expensive because of its manufacturing process and specifications for fluid transport, often making it less available in large dimensions or specialty grades. Your choice should weigh budget constraints and material availability, with structural tubing commonly providing a cost-effective and readily accessible solution for framing and support projects.

Selection Criteria: Which to Choose?

Select structural tubing for applications requiring uniform strength, precise dimensional tolerance, and clean aesthetic appearance, commonly used in construction and framing. Choose pipe when fluid transport or mechanical load-bearing capacity is critical, as it is designed to handle internal pressure and stress with standardized wall thickness. Consider factors such as load type, environmental conditions, and installation requirements to determine the optimal material between structural tubing and pipe.

Conclusion: Structural Tubing vs Pipe Summary

Structural tubing offers consistent shapes and strength ideal for load-bearing frameworks, while pipes are primarily designed for fluid transport with uniform wall thickness and standardized diameters. The choice depends on application requirements: tubing excels in construction and fabrication for rigidity and aesthetics, whereas pipes are preferred in plumbing and fluid conveyance due to pressure ratings and flow efficiency. Understanding these distinctions ensures optimal material selection for engineering projects.

Structural Tubing vs Pipe Infographic

libmatt.com

libmatt.com