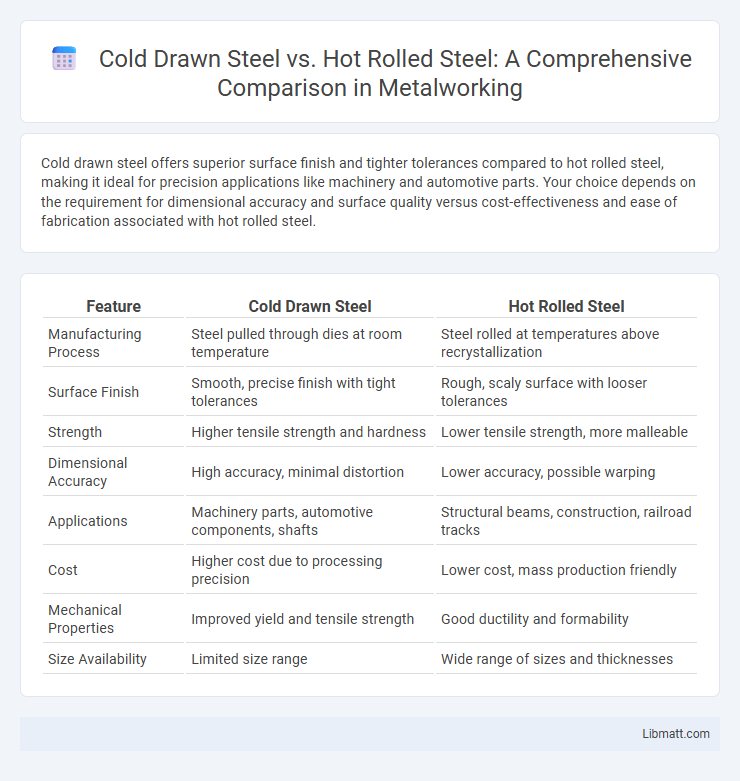

Cold drawn steel offers superior surface finish and tighter tolerances compared to hot rolled steel, making it ideal for precision applications like machinery and automotive parts. Your choice depends on the requirement for dimensional accuracy and surface quality versus cost-effectiveness and ease of fabrication associated with hot rolled steel.

Table of Comparison

| Feature | Cold Drawn Steel | Hot Rolled Steel |

|---|---|---|

| Manufacturing Process | Steel pulled through dies at room temperature | Steel rolled at temperatures above recrystallization |

| Surface Finish | Smooth, precise finish with tight tolerances | Rough, scaly surface with looser tolerances |

| Strength | Higher tensile strength and hardness | Lower tensile strength, more malleable |

| Dimensional Accuracy | High accuracy, minimal distortion | Lower accuracy, possible warping |

| Applications | Machinery parts, automotive components, shafts | Structural beams, construction, railroad tracks |

| Cost | Higher cost due to processing precision | Lower cost, mass production friendly |

| Mechanical Properties | Improved yield and tensile strength | Good ductility and formability |

| Size Availability | Limited size range | Wide range of sizes and thicknesses |

Introduction to Cold Drawn and Hot Rolled Steel

Cold drawn steel undergoes a precise finishing process that enhances strength, surface finish, and dimensional accuracy by drawing the metal through dies at room temperature. Hot rolled steel, produced by rolling the metal at high temperatures above its recrystallization point, offers improved ductility and is more cost-effective for large structural applications. Your choice between cold drawn and hot rolled steel depends on the balance between mechanical properties, surface quality, and budget requirements.

Understanding the Manufacturing Processes

Cold drawn steel undergoes a manufacturing process where the steel is pulled through a die below its recrystallization temperature, resulting in improved surface finish, tighter tolerances, and increased strength due to strain hardening. Hot rolled steel is formed by rolling the steel at high temperatures above its recrystallization point, producing larger, coarser grains with a rougher surface and more malleable properties. The manufacturing differences between cold drawn and hot rolled steel directly impact mechanical properties, dimensional accuracy, and application suitability in construction and manufacturing industries.

Key Differences in Physical Properties

Cold drawn steel exhibits higher tensile strength, improved surface finish, and tighter dimensional tolerances compared to hot rolled steel. Hot rolled steel typically has a rougher surface texture, more malleability, and residual stresses due to the cooling process after rolling. The refined grain structure in cold drawn steel enhances hardness and yield strength, making it suitable for precision applications.

Surface Finish Comparison

Cold drawn steel features a smooth, precise surface finish with tighter dimensional tolerances compared to hot rolled steel, which has a rougher texture due to the cooling process. The enhanced surface quality of cold drawn steel reduces the need for additional machining, making it ideal for applications requiring high aesthetic standards or minimal surface treatment. Your choice between the two depends on the desired surface finish and the intended use in manufacturing or construction projects.

Strength and Durability Analysis

Cold drawn steel exhibits higher tensile strength and improved surface finish due to work hardening during the drawing process, making it ideal for applications requiring precise dimensions and enhanced durability. In contrast, hot rolled steel has a rougher surface with lower tensile strength as it is processed at high temperatures, which can lead to increased ductility but less structural rigidity. For strength-critical components where hardness and dimensional accuracy are priorities, cold drawn steel outperforms hot rolled steel in long-term durability and resistance to fatigue.

Applications and Industry Uses

Cold drawn steel offers superior surface finish and dimensional accuracy, making it ideal for precision parts in automotive, aerospace, and machinery industries. Hot rolled steel's greater malleability suits heavy construction, railways, and structural components where strength and cost-effectiveness are prioritized. Your choice depends on whether you need fine detail and strength or large-scale durability and flexibility in industrial applications.

Cost Considerations and Budget Impact

Cold drawn steel typically incurs higher costs than hot rolled steel due to its precise manufacturing process and enhanced mechanical properties. Your budget may be impacted by the premium pricing of cold drawn steel, which offers tighter tolerances and superior surface finish ideal for applications requiring accuracy and strength. Hot rolled steel presents a more economical option for projects where dimensional precision is less critical, helping to optimize overall material expenses.

Tolerance and Dimensional Accuracy

Cold drawn steel offers superior tolerance and dimensional accuracy compared to hot rolled steel due to its manufacturing process, which involves pulling the steel through a die to achieve precise dimensions. Hot rolled steel, cooled at high temperatures, typically has looser tolerances and less predictable surface finishes, leading to slight variations in size and shape. Industries requiring exact measurements and tight tolerances, such as automotive and machinery manufacturing, often prefer cold drawn steel for its reliable consistency and minimal machining requirements.

Pros and Cons of Cold Drawn Steel

Cold drawn steel offers superior dimensional accuracy, improved surface finish, and higher tensile strength compared to hot rolled steel. However, it typically has higher production costs and limited availability in larger sizes. The enhanced mechanical properties of cold drawn steel make it ideal for precision applications, while hot rolled steel remains preferred for structural components due to cost efficiency and easier machinability.

Pros and Cons of Hot Rolled Steel

Hot rolled steel offers superior ductility and is generally more cost-effective than cold drawn steel, making it ideal for applications requiring large-scale structural components. Its manufacturing process enhances material toughness but results in less precise dimensions and a rougher surface finish, which may require additional machining. You should consider hot rolled steel when strength and affordability outweigh the need for exact tolerances or smooth aesthetics.

Cold Drawn Steel vs Hot Rolled Steel Infographic

libmatt.com

libmatt.com