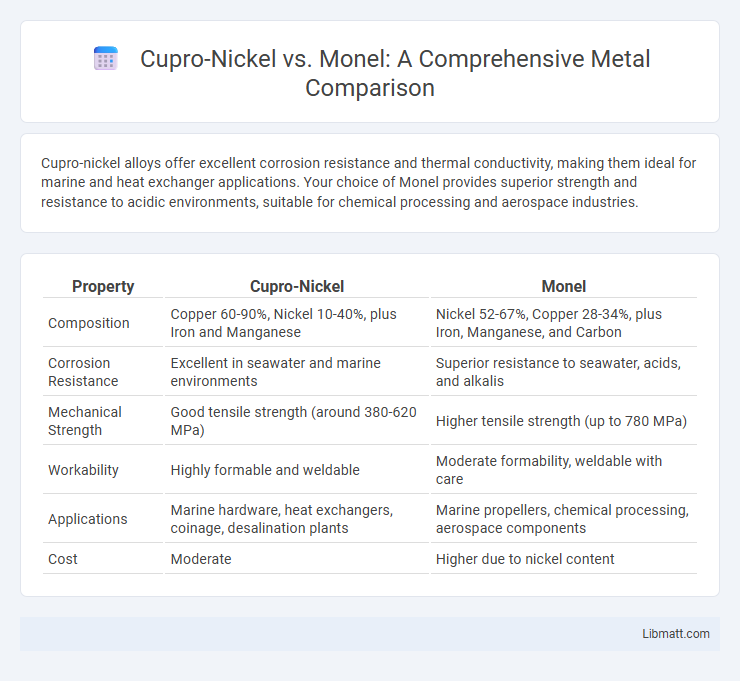

Cupro-nickel alloys offer excellent corrosion resistance and thermal conductivity, making them ideal for marine and heat exchanger applications. Your choice of Monel provides superior strength and resistance to acidic environments, suitable for chemical processing and aerospace industries.

Table of Comparison

| Property | Cupro-Nickel | Monel |

|---|---|---|

| Composition | Copper 60-90%, Nickel 10-40%, plus Iron and Manganese | Nickel 52-67%, Copper 28-34%, plus Iron, Manganese, and Carbon |

| Corrosion Resistance | Excellent in seawater and marine environments | Superior resistance to seawater, acids, and alkalis |

| Mechanical Strength | Good tensile strength (around 380-620 MPa) | Higher tensile strength (up to 780 MPa) |

| Workability | Highly formable and weldable | Moderate formability, weldable with care |

| Applications | Marine hardware, heat exchangers, coinage, desalination plants | Marine propellers, chemical processing, aerospace components |

| Cost | Moderate | Higher due to nickel content |

Introduction to Cupro-Nickel and Monel

Cupro-nickel and Monel are both corrosion-resistant alloys widely used in marine and industrial applications due to their exceptional durability in harsh environments. Cupro-nickel primarily consists of copper and nickel, typically with copper content ranging from 70% to 90%, offering excellent resistance to seawater corrosion and biofouling. Monel is a nickel-copper alloy with a higher nickel content, usually around 65-70%, known for its superior strength and resistance to acids, making it ideal for chemical processing and marine hardware.

Chemical Composition Comparison

Cupro-nickel typically contains 70% copper and 30% nickel with small amounts of iron and manganese, providing excellent corrosion resistance in marine environments. Monel alloys, such as Monel 400, have a higher nickel content, around 65-70%, along with more copper and traces of iron and manganese, resulting in greater strength and resistance to acidic environments. Understanding these chemical composition differences helps you select the ideal alloy for corrosion resistance or mechanical performance in your specific application.

Mechanical Properties and Strength

Cupro-nickel alloys offer excellent corrosion resistance with moderate tensile strength, typically ranging from 370 to 620 MPa, making them suitable for marine applications where durability is essential. Monel alloys exhibit superior mechanical properties with tensile strength often exceeding 700 MPa and enhanced toughness, providing greater resistance to wear and fatigue in demanding environments. Your choice depends on whether higher strength and toughness (Monel) or balanced corrosion resistance and strength (Cupro-nickel) better suit your project's mechanical requirements.

Corrosion Resistance Analysis

Cupro-nickel alloys exhibit exceptional corrosion resistance in seawater environments due to their high copper content, which promotes the formation of a protective oxide layer. Monel, primarily composed of nickel and copper, offers superior resistance to both acidic and alkaline conditions, making it ideal for chemical processing applications. While Cupro-nickel is more cost-effective for marine applications, Monel's robustness against pitting, crevice corrosion, and stress corrosion cracking gives it an advantage in aggressive industrial environments.

Temperature and Thermal Conductivity

Cupro-nickel alloys typically maintain excellent thermal conductivity between 30 and 40 W/m*K, making them suitable for heat exchangers with operating temperatures up to 400degC. Monel, an alloy primarily of nickel and copper, exhibits lower thermal conductivity around 20 W/m*K but withstands higher temperatures exceeding 600degC without significant deformation. When comparing Cupro-nickel vs Monel for your applications, consider that Cupro-nickel offers better heat transfer efficiency, while Monel is preferable for high-temperature resistance.

Common Applications and Uses

Cupro-nickel alloys are commonly used in marine environments for ship hulls, seawater piping, and desalination plants due to their excellent corrosion resistance and biofouling resistance. Monel is favored in chemical processing, aerospace, and marine hardware applications where strength and resistance to acids, alkalis, and saltwater are critical. Your choice between cupro-nickel and monel will depend on the specific environmental conditions and mechanical requirements of your project.

Workability and Fabrication

Cupro-nickel alloys exhibit excellent workability with superior corrosion resistance, making them ideal for marine and heat exchanger applications where seamless fabrication is essential. Monel, predominantly composed of nickel and copper, offers outstanding strength and toughness but requires specialized machining and welding techniques due to its high strength and work hardening characteristics. Fabrication of cupro-nickel is generally easier and less costly compared to monel, which demands more precise control to avoid cracking and maintain mechanical integrity.

Cost and Availability

Cupro-nickel is generally more cost-effective and widely available than Monel due to its simpler alloy composition primarily consisting of copper and nickel. Monel, an alloy with higher nickel content and added elements like copper and iron, tends to be more expensive and less readily stocked by suppliers. Your choice depends on budget constraints and the specific availability of materials in your region's market.

Maintenance and Longevity

Cupro-nickel alloys offer exceptional corrosion resistance in marine environments, reducing maintenance needs and extending lifespan by preventing rust and biofouling. Monel metal, known for its superior strength and toughness, withstands high-stress applications while resisting pitting and crevice corrosion, contributing to long-lasting durability with minimal upkeep. Both materials deliver excellent longevity, but cupro-nickel is often preferred where lower maintenance in seawater exposure is critical.

Choosing Between Cupro-Nickel and Monel

Choosing between cupro-nickel and Monel depends on your specific application requirements, such as corrosion resistance, strength, and thermal conductivity. Cupro-nickel offers superior resistance to seawater corrosion and excellent thermal conductivity, making it ideal for marine and heat exchanger applications. Monel provides higher strength and exceptional resistance to acidic environments, which suits chemical processing and aerospace industries better.

Cupro-nickel vs monel Infographic

libmatt.com

libmatt.com