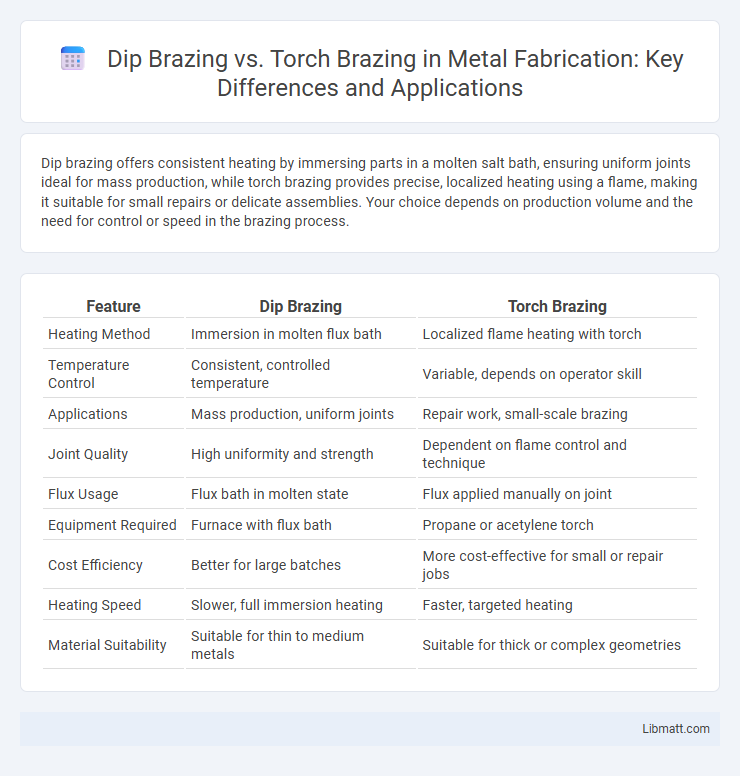

Dip brazing offers consistent heating by immersing parts in a molten salt bath, ensuring uniform joints ideal for mass production, while torch brazing provides precise, localized heating using a flame, making it suitable for small repairs or delicate assemblies. Your choice depends on production volume and the need for control or speed in the brazing process.

Table of Comparison

| Feature | Dip Brazing | Torch Brazing |

|---|---|---|

| Heating Method | Immersion in molten flux bath | Localized flame heating with torch |

| Temperature Control | Consistent, controlled temperature | Variable, depends on operator skill |

| Applications | Mass production, uniform joints | Repair work, small-scale brazing |

| Joint Quality | High uniformity and strength | Dependent on flame control and technique |

| Flux Usage | Flux bath in molten state | Flux applied manually on joint |

| Equipment Required | Furnace with flux bath | Propane or acetylene torch |

| Cost Efficiency | Better for large batches | More cost-effective for small or repair jobs |

| Heating Speed | Slower, full immersion heating | Faster, targeted heating |

| Material Suitability | Suitable for thin to medium metals | Suitable for thick or complex geometries |

Introduction to Brazing Techniques

Dip brazing offers precise temperature control and uniform heating by immersing parts in molten flux, ideal for high-volume, consistent joints. Torch brazing uses a controlled flame to locally heat components, providing flexibility for smaller or complex assemblies. Your choice depends on production scale, joint requirements, and material compatibility.

Overview of Dip Brazing

Dip brazing involves submerging the joint area into a molten salt bath maintained at precise temperatures between 1150degF and 1600degF, ensuring uniform heat distribution and consistent bonding quality. This method offers superior control over the brazing environment compared to torch brazing, reducing oxidation and improving joint strength. Your components benefit from reduced thermal distortion and enhanced mechanical integrity due to the controlled, stable heating process inherent to dip brazing.

Overview of Torch Brazing

Torch brazing utilizes a localized heat source, typically a gas-fueled torch, to melt the filler metal and join metals at temperatures ranging from 1300degF to 1600degF. This method offers precise control over heat application, making it ideal for intricate or small-scale metal assemblies where focused heating prevents damage to surrounding areas. Compared to dip brazing, torch brazing provides faster heating cycles and flexibility in positioning, enhancing efficiency in repair and fabrication processes.

Key Differences Between Dip and Torch Brazing

Dip brazing uses a molten salt bath to heat and join metals uniformly, providing precise temperature control and consistent, high-quality joints for complex assemblies. Torch brazing relies on a localized flame to heat the workpiece, offering greater flexibility for smaller or varied parts but requiring skilled operation to avoid uneven heating. Your choice depends on production volume, part size, and the need for uniformity versus versatility.

Material Compatibility in Dip vs Torch Brazing

Dip brazing offers superior material compatibility for heat-sensitive metals like aluminum and magnesium due to its controlled temperature environment and uniform heating in a molten salt bath. Torch brazing provides flexibility with materials such as steel and copper alloys but risks localized overheating and thermal distortion. Selecting dip brazing is advantageous for joining dissimilar metals requiring precise temperature control, while torch brazing suits applications where accessibility and spot heating are critical.

Process Efficiency and Speed Comparison

Dip brazing offers higher process efficiency and faster cycle times by submerging parts in a molten brazing bath, enabling uniform heating and simultaneous joining of multiple components. Torch brazing requires manual heat application, leading to slower heating rates and less consistent joint quality, which can reduce overall production speed. Your choice between these methods impacts throughput, with dip brazing favored for high-volume manufacturing due to its speed and repeatability advantages.

Quality and Strength of Joints

Dip brazing produces uniform, high-strength joints by immersing parts in molten metal, ensuring consistent heating and superior alloy bonding, ideal for mass production. Torch brazing offers more localized heat control but can result in uneven joint strength and quality due to operator variability and potential overheating. Overall, dip brazing yields stronger, more reliable joints, especially for complex or large-scale assemblies requiring consistent metallurgical properties.

Cost Considerations: Dip vs Torch Brazing

Dip brazing generally offers lower overall costs due to its ability to process multiple parts simultaneously with minimal labor, making it ideal for high-volume production runs. Torch brazing involves higher labor costs and slower throughput as each joint is heated individually, increasing time and energy expenses. Equipment costs for dip brazing are higher upfront, but the efficiency gained in large-scale operations often leads to better cost-effectiveness compared to the flexible but labor-intensive torch brazing method.

Typical Applications for Each Method

Dip brazing is commonly used for small to medium-sized metal components requiring uniform heating, such as electronic connectors, automotive parts, and heat exchangers due to its ability to immerse the workpiece in a molten salt bath for consistent temperature control. Torch brazing suits larger, irregularly shaped, or field-repaired metal assemblies like pipelines, HVAC systems, and heavy machinery where localized, manual heat application provides flexibility and precision. Your choice between dip brazing and torch brazing should consider production volume, part size, and accessibility to optimize joint quality and process efficiency.

Selecting the Best Brazing Method for Your Project

Dip brazing offers uniform heating and is ideal for mass production with consistent joint quality, utilizing a molten salt or metal bath for precise temperature control. Torch brazing provides versatility and localized heating, making it suitable for small-scale projects, repairs, and complex assemblies where access is limited. Selecting the best method depends on factors such as production volume, joint size, material compatibility, and desired thermal control to ensure optimal strength and finish.

Dip brazing vs torch brazing Infographic

libmatt.com

libmatt.com