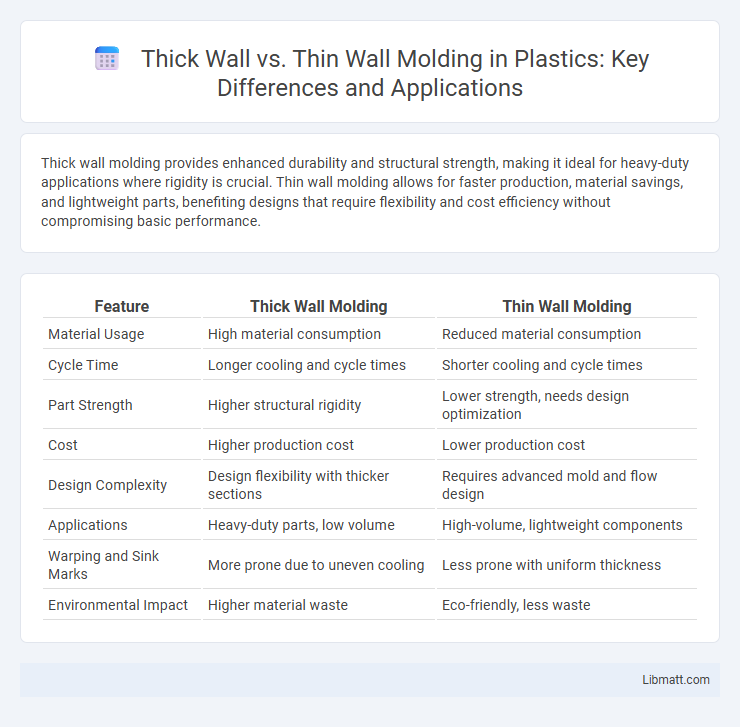

Thick wall molding provides enhanced durability and structural strength, making it ideal for heavy-duty applications where rigidity is crucial. Thin wall molding allows for faster production, material savings, and lightweight parts, benefiting designs that require flexibility and cost efficiency without compromising basic performance.

Table of Comparison

| Feature | Thick Wall Molding | Thin Wall Molding |

|---|---|---|

| Material Usage | High material consumption | Reduced material consumption |

| Cycle Time | Longer cooling and cycle times | Shorter cooling and cycle times |

| Part Strength | Higher structural rigidity | Lower strength, needs design optimization |

| Cost | Higher production cost | Lower production cost |

| Design Complexity | Design flexibility with thicker sections | Requires advanced mold and flow design |

| Applications | Heavy-duty parts, low volume | High-volume, lightweight components |

| Warping and Sink Marks | More prone due to uneven cooling | Less prone with uniform thickness |

| Environmental Impact | Higher material waste | Eco-friendly, less waste |

Introduction to Injection Molding Wall Thickness

Injection molding wall thickness directly impacts part quality, cooling time, and material usage. Thick walls can lead to longer cooling cycles and increased risk of warping or sink marks, while thin walls allow faster production and weight reduction but require precise control to avoid defects like short shots. Optimizing wall thickness balances durability, cost-efficiency, and manufacturing efficiency in injection-molded components.

Defining Thick Wall and Thin Wall Molding

Thick wall molding refers to the production process where plastic walls exceed 4 millimeters in thickness, often used for durable, heavy-duty products requiring high structural integrity. Thin wall molding, in contrast, produces walls typically less than 2 millimeters thick, optimizing material usage and cycle times for lightweight, cost-efficient parts. Understanding the distinction between these techniques helps you select the right molding process based on product strength, weight, and manufacturing speed requirements.

Material Selection for Different Wall Thicknesses

Thick wall molding requires materials with high impact resistance and excellent flow characteristics, such as ABS or polypropylene, to ensure durability and reduce defects like warping. Thin wall molding demands resins with superior flowability and fast cooling properties, like high-flow polycarbonate or specialized grades of nylon, to achieve precise thickness and minimize cycle times. Your material selection directly impacts the molding process efficiency and final product performance based on the wall thickness requirements.

Design Considerations for Thick vs Thin Walls

Design considerations for thick wall molding emphasize managing heat dissipation and minimizing shrinkage, which can lead to warping or sink marks if not properly controlled. Thin wall molding requires precise cavity filling and high injection pressure to ensure complete material flow and maintain structural integrity without defects. Material selection, cooling time, and mold temperature are critical factors influencing the quality and efficiency of both thick and thin wall molded parts.

Impact on Cycle Time and Production Efficiency

Thick wall molding typically increases cycle time due to longer cooling phases, reducing production efficiency by limiting the number of parts produced per hour. Thin wall molding shortens cycle time with faster cooling rates, significantly improving output and lowering energy consumption. Your manufacturing process benefits from optimizing wall thickness to balance structural requirements and maximize cycle efficiency.

Cost Implications of Wall Thickness Choices

Thick wall molding typically incurs higher material and cycle time costs due to increased cooling time and greater raw material usage, impacting overall production expenses. Thin wall molding reduces material consumption and shortens cycle times, resulting in cost savings, but it requires precise mold design and high-quality materials, which may increase initial tooling costs. Your choice between thick and thin wall molding should balance long-term production efficiency against upfront investment to optimize cost-effectiveness.

Mechanical Properties and Structural Integrity

Thick wall molding provides superior mechanical properties such as higher impact resistance and enhanced load-bearing capacity, ensuring robust structural integrity in heavy-duty applications. Thin wall molding offers faster cycle times and material savings but may compromise strength and durability due to its reduced thickness and potential for warping under stress. Selecting the appropriate wall thickness directly affects the part's ability to withstand mechanical forces and long-term performance challenges.

Surface Finish and Aesthetic Differences

Thick wall molding typically results in a less smooth surface finish due to slower cooling rates and potential for warping, leading to visible imperfections and texture variations. Thin wall molding offers superior surface quality with finer details and a more consistent, glossy appearance because of faster cooling and uniform material distribution. These differences significantly impact aesthetic appeal, where thin wall molding is preferred for high-precision, visually demanding applications.

Applications of Thick Wall vs Thin Wall Molding

Thick wall molding is ideal for applications requiring durability and high structural integrity, such as automotive parts, heavy-duty containers, and industrial components. Thin wall molding excels in producing lightweight, cost-effective items with complex geometries, commonly used in packaging, medical devices, and consumer electronics. Your choice between thick and thin wall molding depends on factors like product strength, material usage, and production speed.

Choosing the Right Wall Thickness for Your Project

Selecting the appropriate wall thickness in molding directly impacts strength, weight, and material usage; thick walls provide enhanced durability and structural support, making them ideal for heavy-duty applications. Thin walls offer faster cooling times and reduced material costs, suitable for intricate designs and small parts requiring fine details. Balancing wall thickness with project requirements ensures optimal performance, cost efficiency, and aesthetic quality in molded products.

Thick wall vs thin wall molding Infographic

libmatt.com

libmatt.com