Bladder curing and steam curing are two methods used to accelerate the curing process of concrete, where bladder curing involves inflating a rubber bladder inside a concrete structure to apply pressure and reduce voids, enhancing strength and durability. Steam curing uses controlled steam to elevate temperature and humidity, speeding up hydration and allowing Your concrete to achieve early strength, especially beneficial in precast concrete production.

Table of Comparison

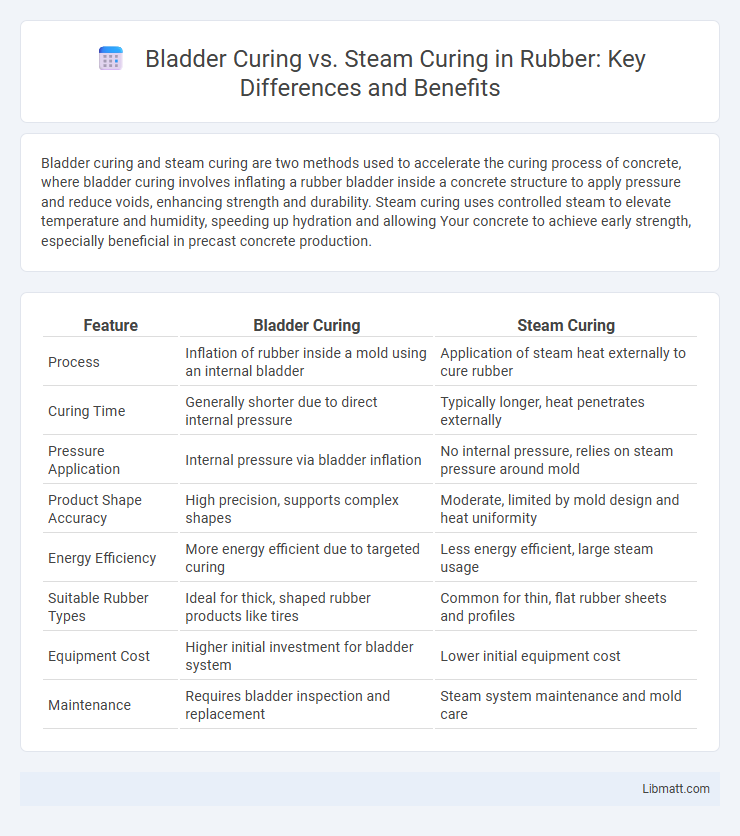

| Feature | Bladder Curing | Steam Curing |

|---|---|---|

| Process | Inflation of rubber inside a mold using an internal bladder | Application of steam heat externally to cure rubber |

| Curing Time | Generally shorter due to direct internal pressure | Typically longer, heat penetrates externally |

| Pressure Application | Internal pressure via bladder inflation | No internal pressure, relies on steam pressure around mold |

| Product Shape Accuracy | High precision, supports complex shapes | Moderate, limited by mold design and heat uniformity |

| Energy Efficiency | More energy efficient due to targeted curing | Less energy efficient, large steam usage |

| Suitable Rubber Types | Ideal for thick, shaped rubber products like tires | Common for thin, flat rubber sheets and profiles |

| Equipment Cost | Higher initial investment for bladder system | Lower initial equipment cost |

| Maintenance | Requires bladder inspection and replacement | Steam system maintenance and mold care |

Introduction to Bladder Curing and Steam Curing

Bladder curing uses inflatable rubber bladders to apply uniform pressure inside concrete pipes or cylinders, enhancing density and strength by preventing deformation during curing. Steam curing accelerates the hydration process by exposing concrete to high-temperature steam, significantly reducing curing time while improving early strength gain. Understanding these methods helps optimize your concrete curing process by balancing mechanical integrity and production efficiency.

Understanding the Curing Process in Tire Manufacturing

Bladder curing and steam curing are essential processes in tire manufacturing that ensure optimal vulcanization of rubber compounds, directly impacting tire performance and durability. Bladder curing involves inflating a rubber bladder inside the tire mold, applying pressure and heat uniformly to shape and cure the tire, while steam curing uses steam to provide consistent heat and moisture during the vulcanization process. Understanding these methods allows you to select the appropriate curing technique that enhances tire strength, flexibility, and lifespan.

What is Bladder Curing?

Bladder curing is a specialized process used primarily in precast concrete pipe manufacturing, where an inflatable rubber bladder inside the pipe applies internal pressure during curing to enhance strength and surface finish. This method improves the density and durability of concrete by preventing micro-cracks and ensuring uniform pressure distribution, resulting in superior structural integrity. Your choice of bladder curing over steam curing can significantly impact the final quality and longevity of concrete products used in infrastructure projects.

What is Steam Curing?

Steam curing is a accelerated concrete curing method that uses high-temperature steam to enhance the hydration process, improving strength and durability rapidly. This technique creates a controlled moist environment, enabling concrete to gain early strength much faster compared to standard curing methods like bladder curing. If you require faster project completion, steam curing offers a reliable solution to achieve optimal concrete performance in less time.

Key Differences Between Bladder and Steam Curing

Bladder curing involves inflating a rubber bladder inside concrete pipes or culverts to apply internal pressure, enhancing strength and surface finish, while steam curing uses moist heat to accelerate the hydration process and early strength gain in concrete products. Key differences include the method of curing--mechanical pressure in bladder curing versus thermal exposure in steam curing--and the resulting impact on concrete density and durability. Understanding these distinctions helps you select the appropriate curing method based on product requirements and production efficiency.

Advantages of Bladder Curing

Bladder curing offers superior pressure application that ensures uniform concrete compaction and reduces voids, enhancing the durability and strength of structural elements. By maintaining consistent internal pressure, bladder curing minimizes surface defects and improves dimensional accuracy compared to steam curing. Your projects benefit from faster curing times and better quality control, resulting in more reliable and long-lasting concrete components.

Advantages of Steam Curing

Steam curing accelerates the hydration process in concrete by providing controlled heat and moisture, resulting in faster strength development compared to bladder curing. This method ensures uniform curing conditions, enhancing durability and reducing the likelihood of surface defects. Steam curing also enables early demolding and quicker project turnaround, making it ideal for precast concrete production.

Common Applications for Each Curing Method

Bladder curing is commonly used in structural and precast concrete elements where controlled pressure and moisture retention enhance strength and durability, such as in pipes, beams, and columns. Steam curing is often applied in precast concrete manufacturing and infrastructure projects like bridges and tunnels, accelerating the hydration process to reduce curing time and improve early strength development. Each method optimizes curing conditions for specific concrete products, improving performance based on project requirements.

Choosing the Right Curing Method for Production

Selecting the optimal curing method between bladder curing and steam curing depends on factors such as production speed, product quality requirements, and cost efficiency. Bladder curing offers uniform pressure and is ideal for complex shapes or large-scale products requiring consistent density and strength. Steam curing provides faster heat transfer and accelerated hydration, making it suitable for high-volume production with shorter curing cycles.

Future Trends in Tire Curing Technologies

Future trends in tire curing technologies highlight the transition from traditional bladder curing to advanced steam curing methods that improve energy efficiency and reduce cycle times. Innovations in microwave and induction heating are being explored to further optimize the curing process, enhancing tire performance and sustainability. Integration of smart sensors and IoT-driven controls aims to enable real-time monitoring and precise regulation of curing conditions, driving higher consistency and reduced waste.

Bladder Curing vs Steam Curing Infographic

libmatt.com

libmatt.com