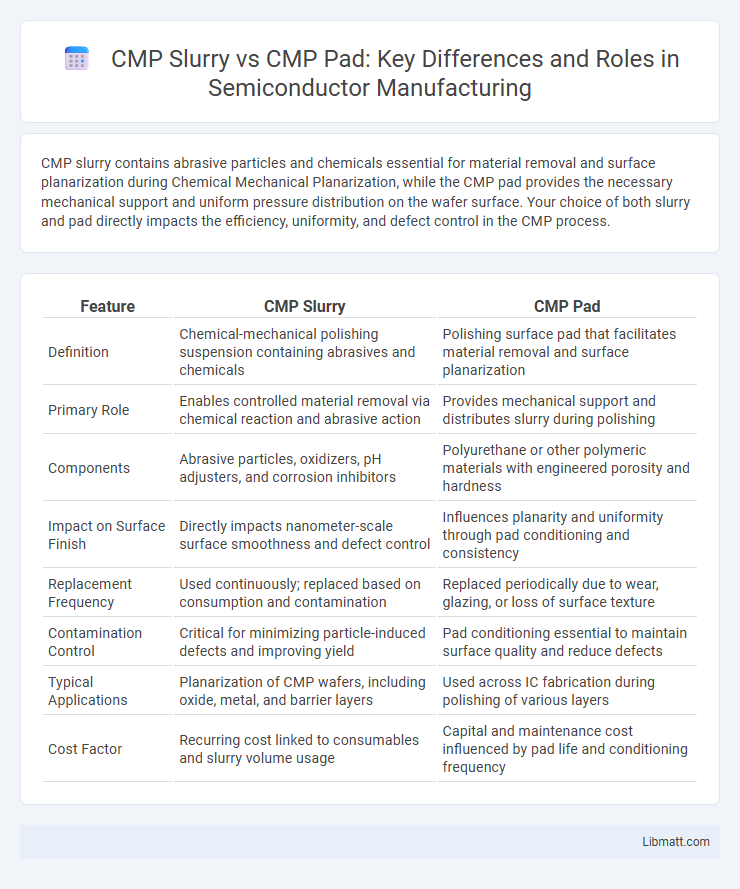

CMP slurry contains abrasive particles and chemicals essential for material removal and surface planarization during Chemical Mechanical Planarization, while the CMP pad provides the necessary mechanical support and uniform pressure distribution on the wafer surface. Your choice of both slurry and pad directly impacts the efficiency, uniformity, and defect control in the CMP process.

Table of Comparison

| Feature | CMP Slurry | CMP Pad |

|---|---|---|

| Definition | Chemical-mechanical polishing suspension containing abrasives and chemicals | Polishing surface pad that facilitates material removal and surface planarization |

| Primary Role | Enables controlled material removal via chemical reaction and abrasive action | Provides mechanical support and distributes slurry during polishing |

| Components | Abrasive particles, oxidizers, pH adjusters, and corrosion inhibitors | Polyurethane or other polymeric materials with engineered porosity and hardness |

| Impact on Surface Finish | Directly impacts nanometer-scale surface smoothness and defect control | Influences planarity and uniformity through pad conditioning and consistency |

| Replacement Frequency | Used continuously; replaced based on consumption and contamination | Replaced periodically due to wear, glazing, or loss of surface texture |

| Contamination Control | Critical for minimizing particle-induced defects and improving yield | Pad conditioning essential to maintain surface quality and reduce defects |

| Typical Applications | Planarization of CMP wafers, including oxide, metal, and barrier layers | Used across IC fabrication during polishing of various layers |

| Cost Factor | Recurring cost linked to consumables and slurry volume usage | Capital and maintenance cost influenced by pad life and conditioning frequency |

Introduction to CMP Slurry and CMP Pad

CMP slurry, a crucial chemical mixture, contains abrasive particles and reactive chemicals designed to facilitate material removal and surface planarization during Chemical Mechanical Planarization. CMP pads, typically composed of polyurethane or other specialized materials, provide the physical interface that applies mechanical force while distributing slurry uniformly across the wafer surface. Both components work synergistically to achieve precise, defect-free wafer polishing critical in semiconductor manufacturing.

Understanding CMP Slurry: Composition and Function

CMP slurry is a crucial abrasive liquid containing nanoparticles, oxidizers, and chemicals designed to facilitate precise material removal during chemical mechanical planarization. Its composition varies depending on the targeted wafer material, optimizing the balance between chemical reactions and mechanical abrasion. The slurry's function ensures uniform surface planarization and defect-free wafer surfaces critical in semiconductor fabrication.

Overview of CMP Pad: Types and Materials

CMP pads are critical components in chemical mechanical planarization, available in various types such as polyurethane pads, porous pads, and fixed abrasive pads, each tailored for specific polishing needs. Polyurethane pads are widely used due to their durability and ability to maintain surface consistency, while porous pads enhance slurry distribution and debris removal. Understanding the materials and types of CMP pads helps optimize your planarization process for improved wafer surface quality and uniformity.

Key Differences Between CMP Slurry and CMP Pad

CMP slurry consists of abrasive particles suspended in a chemical solution, designed to chemically and mechanically remove material from semiconductor wafers. CMP pads are compliant surfaces that provide mechanical support and facilitate uniform polishing during the CMP process. Understanding these key differences can help you optimize the planarization process for improved semiconductor device performance.

Role of CMP Slurry in Chemical Mechanical Planarization

CMP slurry plays a critical role in chemical mechanical planarization by providing the necessary chemical reactants and abrasive particles to effectively remove material from the wafer surface. It facilitates controlled surface modification and mechanical abrasion, ensuring uniform planarization and minimizing defects. The slurry's composition directly impacts the removal rate, selectivity, and wafer surface quality during the CMP process.

Function of CMP Pads in Planarization Process

CMP pads play a crucial role in the planarization process by providing a consistent surface for the chemical mechanical polishing slurry to evenly distribute across the wafer. The pad's texture and porosity are designed to enhance the slurry's abrasive and chemical action, ensuring precise material removal and surface uniformity. Your choice of CMP pad directly impacts the wafer's flatness, defect rate, and overall process efficiency in semiconductor manufacturing.

Performance Impact: Slurry vs Pad in CMP Efficiency

CMP slurry plays a crucial role in enhancing chemical reactions that selectively remove material during the planarization process, directly impacting the uniformity and surface smoothness. CMP pads provide the mechanical aspect by controlling pressure distribution and friction, influencing the removal rate and defectivity. The synergy between slurry chemical composition and pad texture determines overall CMP efficiency, balancing material removal rate, surface quality, and process stability in semiconductor manufacturing.

Compatibility and Interaction: Slurry and Pad Synergy

CMP slurry and CMP pad compatibility is crucial to achieving optimal planarization performance in semiconductor manufacturing. The slurry's chemical composition and abrasive particle size must complement the pad's material porosity, hardness, and surface texture to enhance material removal rates and minimize defects. Effective synergy between slurry and pad promotes uniform polishing, reduces wafer scratches, and extends pad life, directly impacting yield and process consistency.

Common Challenges in Using CMP Slurries and Pads

CMP slurry and CMP pad often face common challenges such as particle contamination and pad wear that impact planarization efficiency and surface quality. Slurry stability issues, including agglomeration and pH fluctuations, can degrade polishing performance, while pad conditioning is critical to maintain uniform material removal rates and prevent scratches. Optimizing slurry chemistry and pad material properties is essential to overcome defects like micro-scratches, erosion, and non-uniform polishing during semiconductor wafer fabrication.

Future Trends in CMP Slurry and Pad Technologies

Emerging trends in CMP slurry and pad technologies emphasize enhanced selectivity, reduced environmental impact, and improved material removal rates to meet the demands of advanced semiconductor manufacturing. Innovations such as nanoparticle-engineered slurries and adaptive CMP pads with real-time surface conditioning enable higher precision and uniformity during wafer planarization. Your ability to leverage these cutting-edge developments can significantly boost process efficiency and yield in next-generation chip fabrication.

CMP Slurry vs CMP Pad Infographic

libmatt.com

libmatt.com