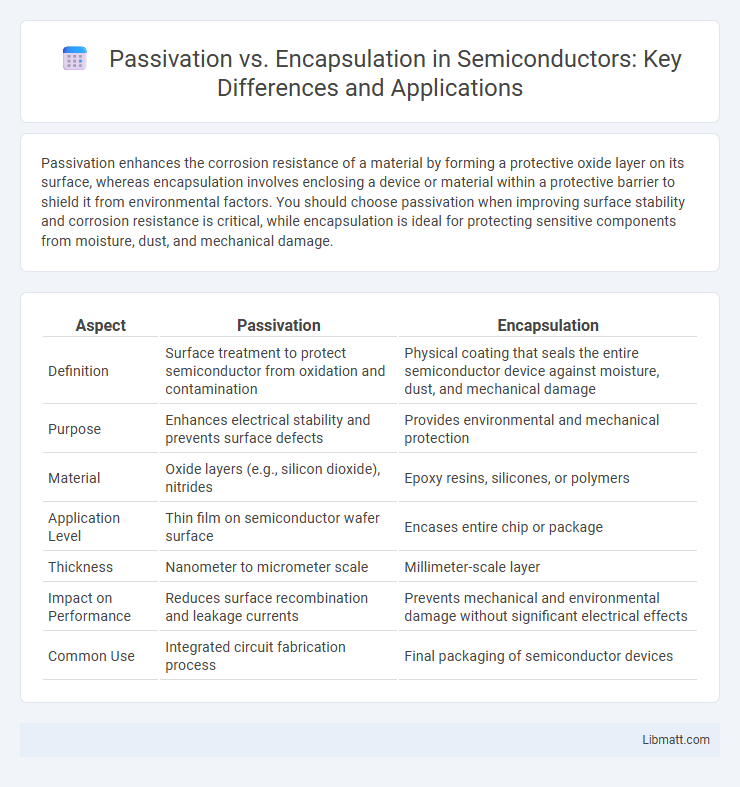

Passivation enhances the corrosion resistance of a material by forming a protective oxide layer on its surface, whereas encapsulation involves enclosing a device or material within a protective barrier to shield it from environmental factors. You should choose passivation when improving surface stability and corrosion resistance is critical, while encapsulation is ideal for protecting sensitive components from moisture, dust, and mechanical damage.

Table of Comparison

| Aspect | Passivation | Encapsulation |

|---|---|---|

| Definition | Surface treatment to protect semiconductor from oxidation and contamination | Physical coating that seals the entire semiconductor device against moisture, dust, and mechanical damage |

| Purpose | Enhances electrical stability and prevents surface defects | Provides environmental and mechanical protection |

| Material | Oxide layers (e.g., silicon dioxide), nitrides | Epoxy resins, silicones, or polymers |

| Application Level | Thin film on semiconductor wafer surface | Encases entire chip or package |

| Thickness | Nanometer to micrometer scale | Millimeter-scale layer |

| Impact on Performance | Reduces surface recombination and leakage currents | Prevents mechanical and environmental damage without significant electrical effects |

| Common Use | Integrated circuit fabrication process | Final packaging of semiconductor devices |

Introduction to Passivation and Encapsulation

Passivation is a chemical process that enhances the corrosion resistance of metal surfaces by creating a protective oxide layer, typically used in stainless steel and aluminum applications. Encapsulation involves enclosing electronic components or materials within a protective barrier, such as polymer resins or silicone, to shield against environmental damage, moisture, and mechanical stress. Both techniques are critical in extending the durability and reliability of materials in various industrial and electronic applications.

Key Definitions: Passivation and Encapsulation

Passivation refers to the chemical process that creates a protective oxide layer on a metal surface to prevent corrosion and enhance durability. Encapsulation involves enclosing electronic components or materials within a protective coating or casing to shield them from physical damage, moisture, and contaminants. Both techniques are crucial in manufacturing for improving the longevity and reliability of metal and electronic materials.

Core Principles of Passivation

Passivation involves creating a protective oxide layer on the surface of a metal or semiconductor to prevent corrosion and enhance durability by reducing chemical reactivity. This process typically uses chemical treatments such as nitric acid or citric acid to remove free iron and form a stable, inert layer. Core principles of passivation emphasize surface purification, oxidation control, and formation of a uniform, adherent passive film that inhibits further surface degradation.

Essential Concepts of Encapsulation

Encapsulation in materials science involves coating a substance with a protective layer to isolate it from environmental factors such as moisture, oxygen, and contaminants, thereby enhancing durability and performance. This process creates a physical barrier that prevents chemical reactions at the surface, preserving the material's integrity and extending its functional lifespan. You can improve product reliability by selecting appropriate encapsulation methods tailored to specific environmental and operational conditions.

Materials Used in Passivation vs Encapsulation

Passivation commonly employs materials such as silicon dioxide (SiO2) and silicon nitride (Si3N4) to form a protective oxide or nitride layer that chemically stabilizes the surface of metals or semiconductors. Encapsulation utilizes polymers like epoxy resins, silicone, or polyurethane to create a physical barrier that protects electronic components from environmental factors such as moisture, dust, and mechanical damage. The key distinction is that passivation chemically modifies the surface for corrosion resistance, while encapsulation physically isolates and shields the component.

Applications in Electronics and Materials Science

Passivation enhances electronic device performance by forming a protective oxide layer that prevents corrosion and surface defects in semiconductors, while encapsulation involves enclosing components in a protective material to shield them from environmental factors like moisture and mechanical damage. In materials science, passivation improves metal durability and chemical resistance, especially in stainless steel and aluminum alloys, whereas encapsulation is crucial for packaging sensitive materials such as sensors, batteries, and polymers to maintain stability. Understanding the differences between these techniques helps optimize your electronic designs and material longevity for specific application requirements.

Benefits and Limitations Compared

Passivation enhances corrosion resistance by forming a protective oxide layer on metal surfaces, significantly extending material lifespan in harsh environments, but it may be less effective against physical damage or mechanical wear. Encapsulation provides comprehensive protection by fully sealing components with polymers or resins, preventing moisture and chemical ingress, yet it can add weight and reduce heat dissipation. While passivation is cost-effective and suitable for thin metal parts, encapsulation offers superior environmental sealing at the expense of potential complexity and bulk.

Processing Techniques and Technologies

Passivation utilizes chemical treatments like oxide layer formation through thermal oxidation or chemical vapor deposition to protect semiconductor surfaces from contamination and corrosion. Encapsulation involves advanced polymer coatings, such as epoxy resins or silicone gels, applied via processes like potting, molding, or conformal coating to shield electronic components from environmental factors and mechanical stress. Your choice of processing techniques directly impacts device reliability and longevity, with passivation favoring thin-film surface stabilization and encapsulation providing robust physical protection.

Selection Criteria: When to Use Each Method

Passivation is ideal for protecting semiconductor surfaces by forming a thin, chemically stable oxide layer that minimizes surface states and enhances device performance, making it suitable for applications requiring improved electrical stability and corrosion resistance. Encapsulation provides robust mechanical protection and environmental isolation by enclosing components in polymer or resin materials, which is essential when shielding electronics from moisture, dust, and physical damage. Your choice depends on whether the priority is surface chemical protection (passivation) or comprehensive environmental and mechanical barrier (encapsulation).

Future Trends and Innovations

Future trends in passivation emphasize the development of advanced thin-film coatings using atomic layer deposition to enhance corrosion resistance and electronic stability. Innovations in encapsulation focus on flexible, transparent barrier materials with improved environmental durability for electronics and photovoltaics. Both techniques increasingly integrate nanotechnology to boost performance and enable multifunctional protective layers in emerging applications.

Passivation vs Encapsulation Infographic

libmatt.com

libmatt.com