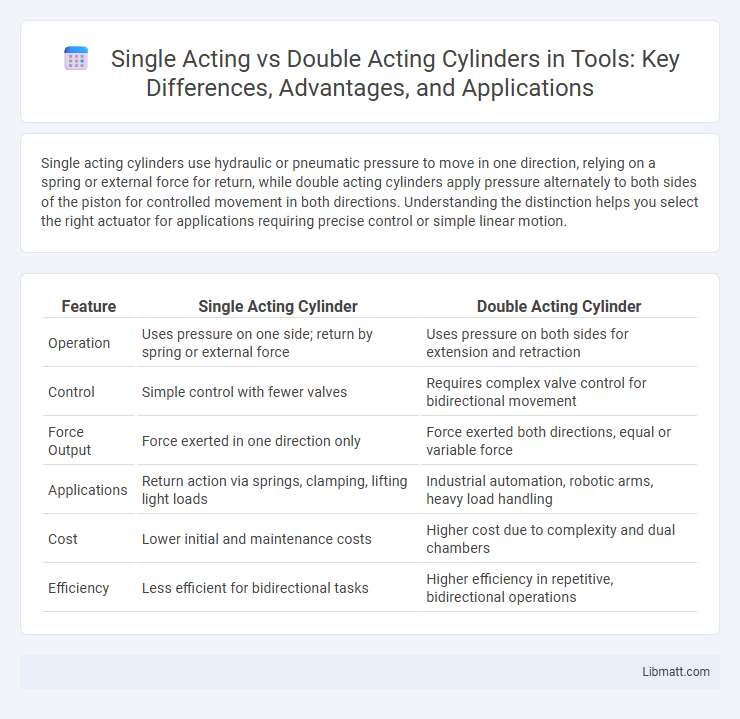

Single acting cylinders use hydraulic or pneumatic pressure to move in one direction, relying on a spring or external force for return, while double acting cylinders apply pressure alternately to both sides of the piston for controlled movement in both directions. Understanding the distinction helps you select the right actuator for applications requiring precise control or simple linear motion.

Table of Comparison

| Feature | Single Acting Cylinder | Double Acting Cylinder |

|---|---|---|

| Operation | Uses pressure on one side; return by spring or external force | Uses pressure on both sides for extension and retraction |

| Control | Simple control with fewer valves | Requires complex valve control for bidirectional movement |

| Force Output | Force exerted in one direction only | Force exerted both directions, equal or variable force |

| Applications | Return action via springs, clamping, lifting light loads | Industrial automation, robotic arms, heavy load handling |

| Cost | Lower initial and maintenance costs | Higher cost due to complexity and dual chambers |

| Efficiency | Less efficient for bidirectional tasks | Higher efficiency in repetitive, bidirectional operations |

Introduction to Hydraulic Cylinders

Single acting cylinders use hydraulic pressure to move the piston in one direction while relying on a spring or external force to return it, making them ideal for simple lifting and pressing tasks with lower cost and maintenance. Double acting cylinders apply hydraulic pressure on both sides of the piston, enabling controlled movement in both directions, which provides greater precision and power for complex industrial applications such as automation and heavy machinery. Hydraulic cylinders, whether single or double acting, convert fluid energy into linear mechanical force, playing a crucial role in hydraulic systems for construction, manufacturing, and automotive industries.

What is a Single Acting Cylinder?

A single acting cylinder uses hydraulic or pneumatic pressure to move the piston in one direction while a spring or external force returns it to its original position. This type of cylinder is simpler and more cost-effective, ideal for applications requiring only one power stroke. You can find single acting cylinders commonly used in clamping, lifting, or ejecting operations where control is needed in one direction only.

What is a Double Acting Cylinder?

A double acting cylinder is a pneumatic or hydraulic actuator that uses pressure to move the piston in both directions, providing controlled force during extension and retraction. Unlike single acting cylinders, which rely on external forces like springs for the return stroke, double acting cylinders offer precise motion control and higher efficiency in industrial automation. Their bidirectional operation makes them ideal for applications requiring repetitive and consistent pushing and pulling actions.

Core Differences Between Single and Double Acting Cylinders

Single acting cylinders use hydraulic or pneumatic pressure to move the piston in one direction, relying on a spring or external force for the return stroke. Double acting cylinders apply pressure alternately to both sides of the piston, enabling controlled movement in both extension and retraction. This fundamental difference affects applications, with single acting cylinders suited for simple tasks requiring only one powered movement and double acting cylinders preferred for precise control and higher force in both directions.

Working Principles Explained

A single acting cylinder uses air pressure or hydraulic fluid to extend the piston in one direction while a spring or external force returns it to its original position, making it ideal for applications requiring force in only one direction. Double acting cylinders apply pressure alternately on both sides of the piston, enabling controlled movement in both extension and retraction strokes for precise positioning and greater power. This fundamental difference in working principles determines their suitability for tasks demanding force in a single direction versus tasks needing bidirectional control.

Applications of Single Acting Cylinders

Single acting cylinders are commonly used in applications that require a simple and cost-effective solution for tasks involving pushing or lifting with a return mechanism provided by a spring or external force. These cylinders are ideal for operations such as clamping, ejecting, or lifting in automotive assembly lines, packaging machinery, and agricultural equipment. Their design simplicity makes them suitable for repetitive tasks where movement in only one direction is powered, reducing complexity and maintenance needs.

Applications of Double Acting Cylinders

Double acting cylinders find extensive applications in industrial automation, where controlled movement in both directions is essential for tasks such as pressing, stamping, and lifting. They are commonly used in robotic arms, manufacturing machinery, and heavy equipment to provide precise force and motion control. Their ability to extend and retract under pressure makes them ideal for environments requiring reciprocating motion and consistent performance.

Advantages and Disadvantages Comparison

Single acting cylinders offer simplicity and lower cost due to their single power stroke, making them ideal for applications with limited space or lighter loads, but they rely on springs or external forces to return, which limits control and speed. Double acting cylinders provide more precise control with power supplied in both directions, suitable for heavy-duty applications requiring faster and more consistent motion, though they are more complex, expensive, and require dual pneumatic or hydraulic lines. The choice depends on balancing cost, control precision, force requirements, and application complexity.

How to Choose Between Single and Double Acting Cylinders

Choosing between single acting and double acting cylinders depends on the application's force requirements and motion control. Single acting cylinders use air or hydraulic pressure to move in one direction and rely on a spring or external force for retraction, making them ideal for simple, low-cost operations with limited stroke needs. Double acting cylinders provide controlled movement in both directions through fluid pressure, offering greater precision and power for complex industrial machinery or automated systems.

Conclusion: Which Cylinder Type Suits Your Needs?

Single acting cylinders are ideal for applications requiring a simple push or pull motion with a single power stroke and spring return, making them cost-effective and energy-efficient for light-duty tasks. Double acting cylinders provide power in both extending and retracting strokes, offering higher precision and force control suited for heavy-duty, continuous, or complex automation processes. Selecting the right cylinder depends on your specific force requirements, motion control needs, and operational complexity.

Single acting cylinder vs double acting cylinder Infographic

libmatt.com

libmatt.com